Industry Knowledge

What are the advantages of using aluminum high pressure die-casting for manufacturing auto parts compared to other methods

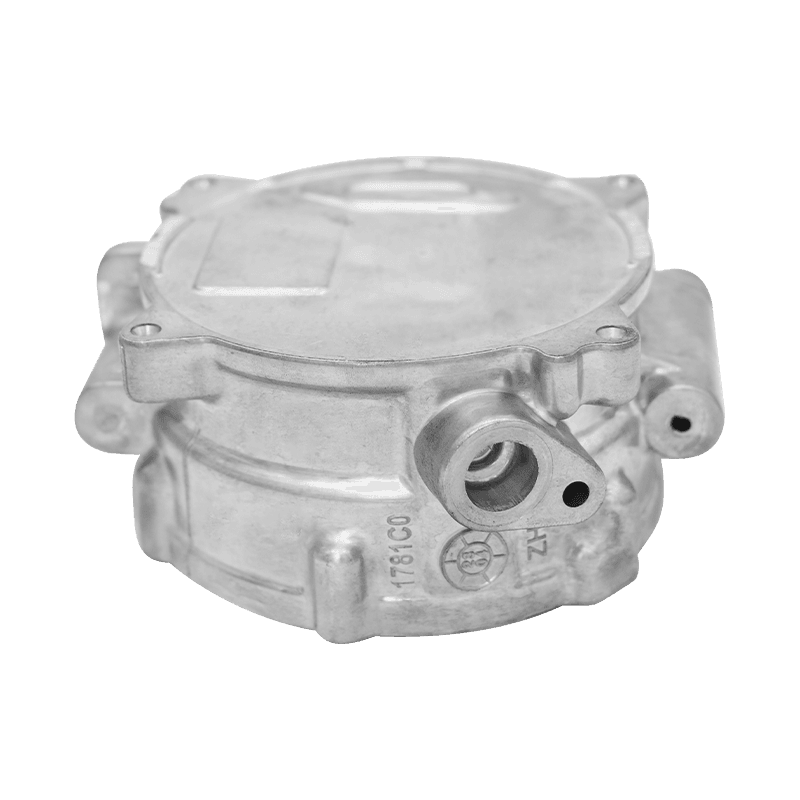

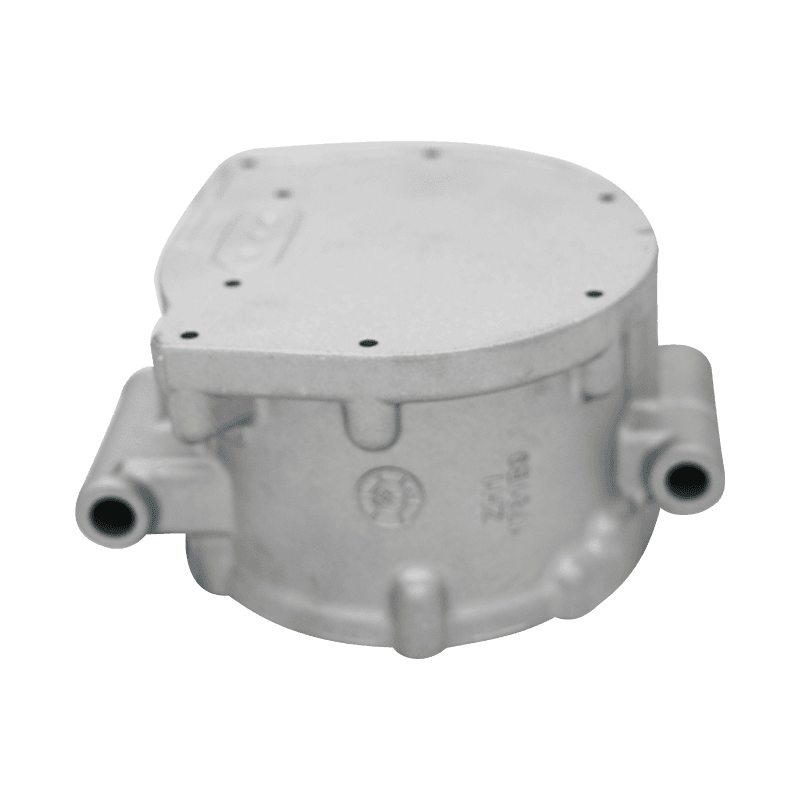

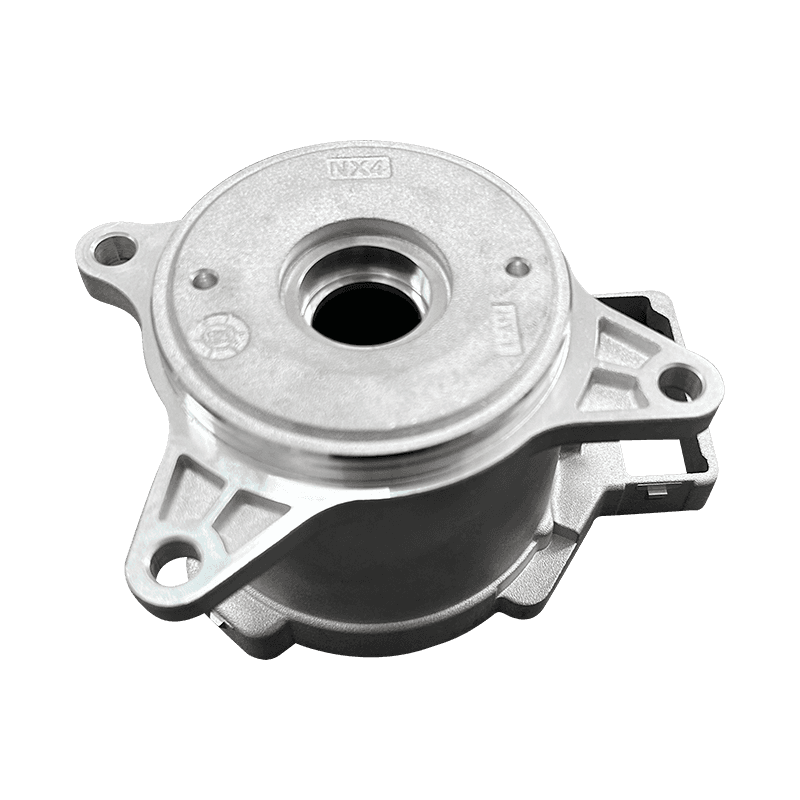

High strength and durability: Aluminum die-cast parts are known for their high strength and durability, making them ideal for use in automotive applications where parts need to withstand high stress and wear.

High accuracy and consistency: HPDC produces parts with high dimensional accuracy and consistency, reducing the need for post-processing and ensuring that parts fit together correctly and function properly.

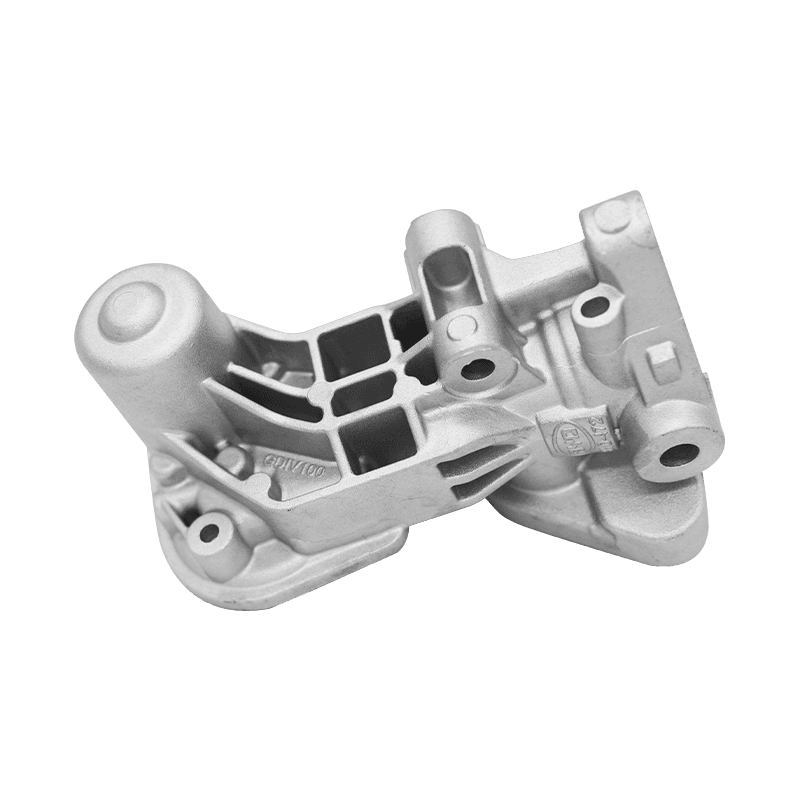

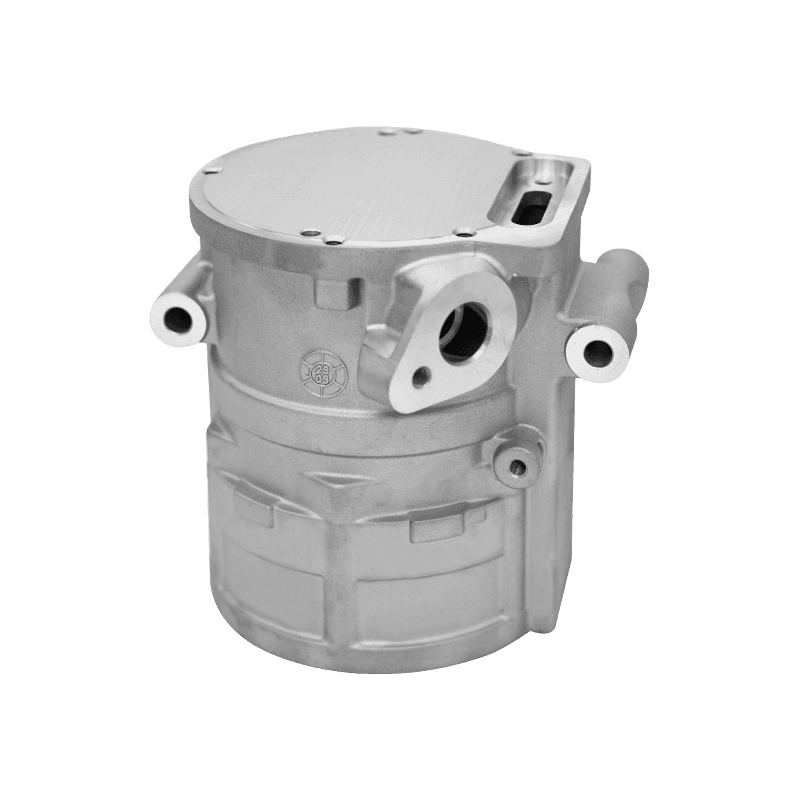

Complex shapes: The HPDC process allows for the production of complex shapes with thin walls and intricate details that would be difficult or impossible to achieve with other methods.

Reduced weight: Aluminum die-cast parts are lightweight, which can help improve fuel efficiency and reduce emissions.

Cost-effectiveness: HPDC is a highly automated process that can produce large volumes of parts quickly and efficiently, reducing production costs and lead times.

Recyclability: Aluminum is a highly recyclable material, making it an environmentally friendly choice for auto parts production.

What are some of the challenges associated with producing high pressure die-casted aluminum auto parts

Porosity: The high pressure used in the process can create small voids or pores in the castings, which can lead to weaker parts and potential failure.

Dimensional accuracy: Maintaining consistent dimensional accuracy in the final product can be a challenge due to the thermal and mechanical stresses involved in the process.

Surface finish: Achieving a smooth and consistent surface finish can be difficult, and additional post-casting processing may be required.

Tooling and maintenance: High pressure die casting requires complex and expensive tooling, and regular maintenance and replacement of these tools is necessary to ensure quality and consistency.

Material selection: Choosing the appropriate aluminum alloy for the specific part and application is crucial, as different alloys have varying mechanical properties that can impact the part's performance and durability.

How has the demand for aluminum high pressure die-casted auto parts changed in recent years

One of the primary reasons for the increased demand for high-pressure die-casted aluminum auto parts is the need for more fuel-efficient vehicles. With the global focus on reducing greenhouse gas emissions and improving fuel economy, auto manufacturers are turning to lightweight materials like aluminum to make their vehicles more fuel-efficient. By reducing the weight of vehicles, manufacturers can improve fuel economy, reduce emissions, and comply with stricter environmental regulations.

Another reason for the increased demand for aluminum auto parts is the growing trend towards electric and hybrid vehicles. These vehicles require lightweight materials to offset the weight of the battery packs and other electric components, and aluminum is an ideal choice. By using high-pressure die-casting to produce aluminum auto parts, manufacturers can create complex shapes and intricate designs that are difficult to achieve with other manufacturing methods.

In addition, the increasing demand for safety features in vehicles has led to the use of more complex and sophisticated auto parts. High-pressure die-casting allows for the production of intricate and complex auto parts with high precision, making it an ideal choice for the manufacturing of safety-critical components like steering and suspension systems, brake components, and other vital parts.

cn

cn English

English Español

Español