Industry Knowledge

What are some examples of aluminum low pressure die-cast auto parts, and what are their functions within the vehicle

Aluminum low pressure die-casting is a popular manufacturing method used to produce a wide range of auto parts. Some examples of aluminum low pressure die-cast auto parts include:

Engine blocks: The engine block is the main structure of the engine and houses the cylinders, pistons, and other key components.

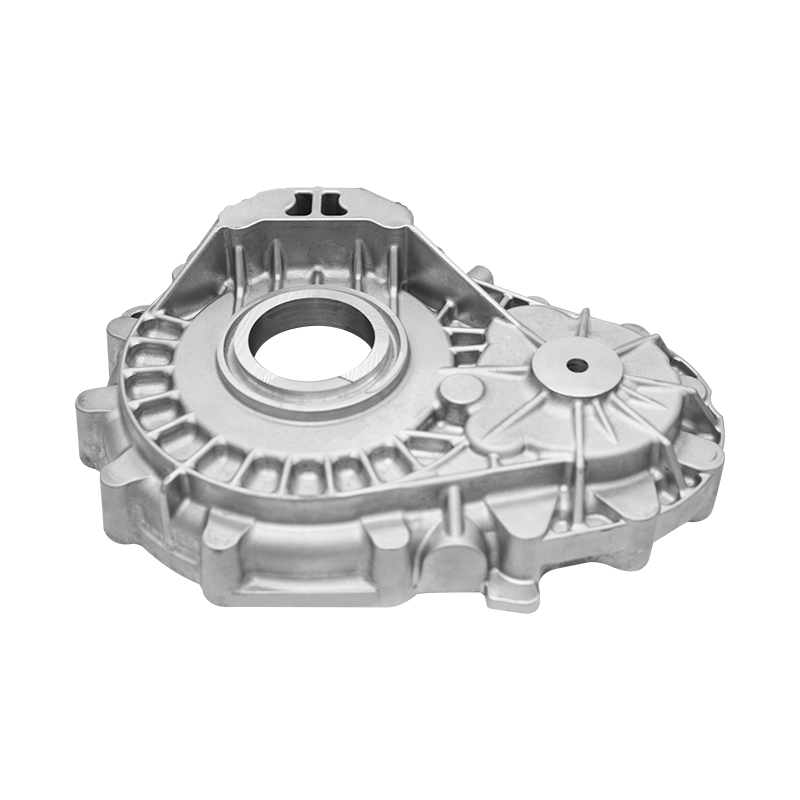

Transmission cases: The transmission case is the outer shell that contains the gears and other components of the vehicle's transmission system.

Wheels: Many high-performance and lightweight wheels are made using aluminum low pressure die-casting.

Suspension components: Various suspension components, such as control arms, steering knuckles, and hubs, are also commonly made using this method.

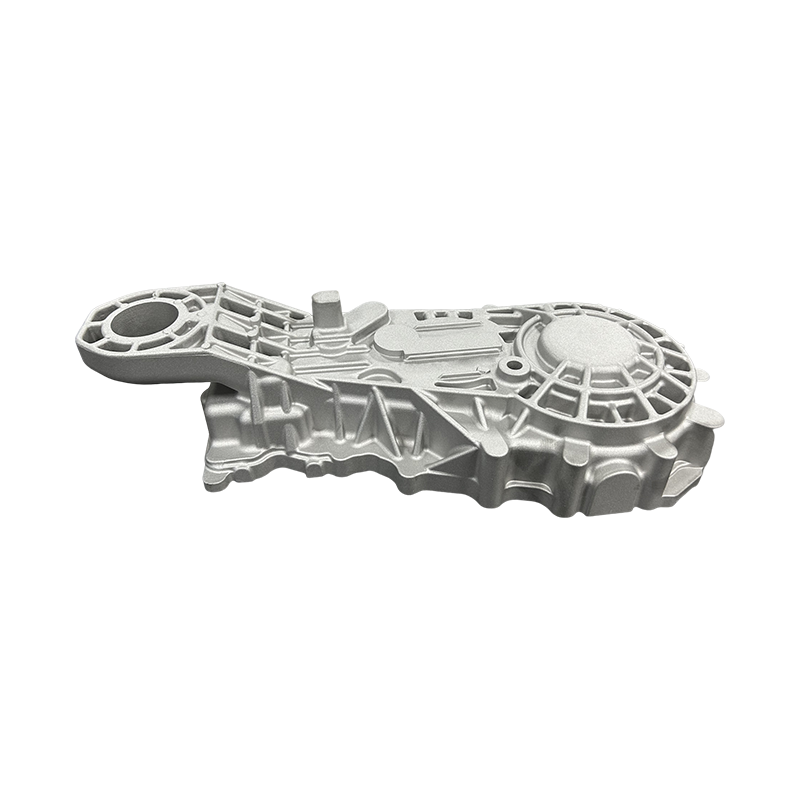

Intake manifolds: The intake manifold is a component of the engine that delivers air to the cylinders.

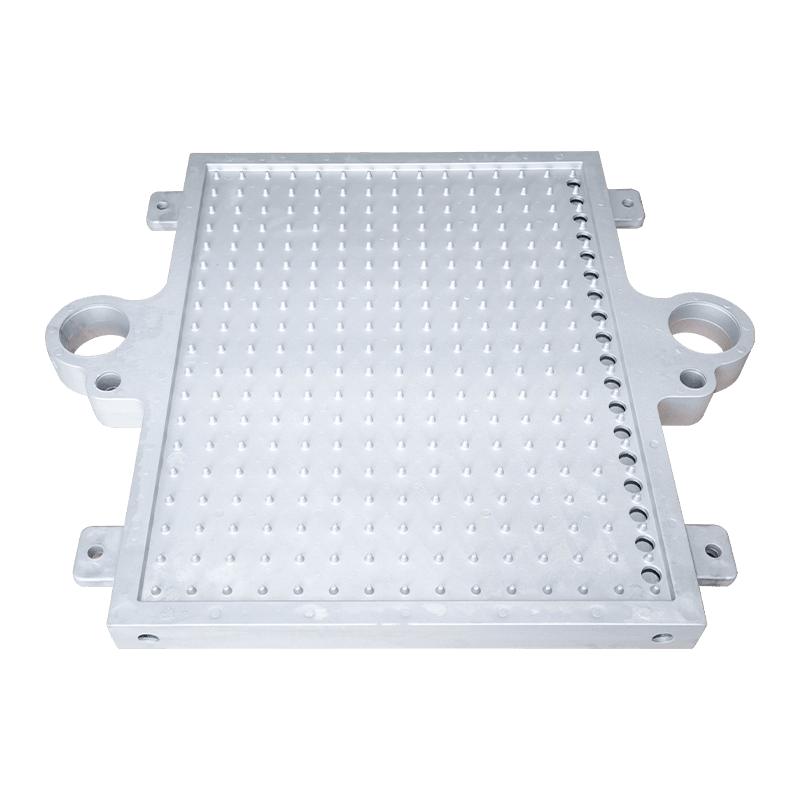

Oil pans: The oil pan is a component of the engine that collects and holds the engine oil.

How are aluminum low pressure die-cast auto parts designed and engineered, and what factors need to be considered during the process

Aluminum low pressure die-cast auto parts are designed and engineered using advanced computer-aided design (CAD) software, which allows designers to create detailed, three-dimensional models of the parts. This process involves several key steps, including:

Conceptual design: In the first stage of the process, designers work with engineers and other stakeholders to identify the key specifications and requirements for the part. This involves considering factors such as the vehicle's performance, weight, and cost, as well as any regulatory or safety requirements.

3D modeling: Once the design concept is finalized, designers use CAD software to create a detailed 3D model of the part. This model includes all of the part's features, such as its shape, size, and material properties.

Simulation and testing: After the 3D model is created, engineers use advanced simulation and testing software to evaluate the part's performance under various conditions. This helps to identify any potential issues or areas for improvement.

What are some of the best practices for maintaining and repairing aluminum low pressure die-cast auto parts, and how can fleet managers and owners ensure that these parts continue to perform effectively over the long term

Maintaining and repairing aluminum low pressure die-cast auto parts requires proper care and attention to ensure that they continue to perform effectively over the long term. Here are some best practices for maintaining and repairing these parts:

Regular inspections: Conduct regular visual inspections of the parts to identify any signs of wear and tear, cracks, or other damage. This can help to identify potential issues before they become more serious.

Proper cleaning: Clean the parts using a mild detergent and a soft-bristled brush to remove any dirt, grime, or debris that may have accumulated on the surface.

Lubrication: Lubricate the moving parts of the assembly to reduce friction and wear, which can extend the lifespan of the parts.

Proper storage: Store the parts in a cool, dry place away from direct sunlight and moisture to prevent rust and corrosion.

cn

cn English

English Español

Español