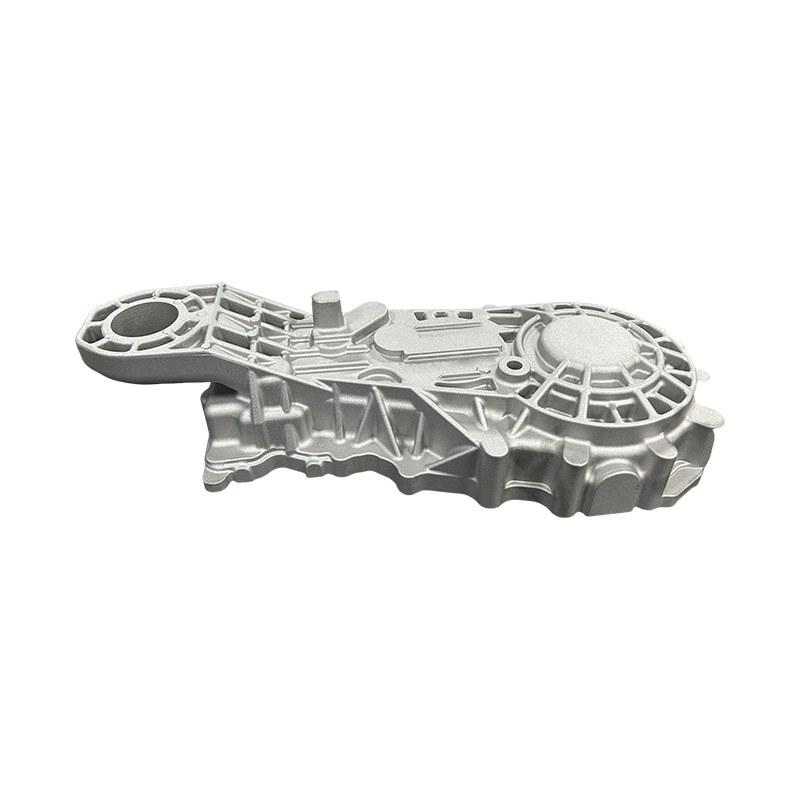

The lightweight nature of aluminum die-cast EV (Electric Vehicle) parts has become increasingly critical in the automotive industry's transition towards electric mobility. As automakers strive to develop electric vehicles with longer ranges, faster charging times, and improved overall efficiency, the weight of vehicle components has emerged as a crucial factor in achieving these objectives.

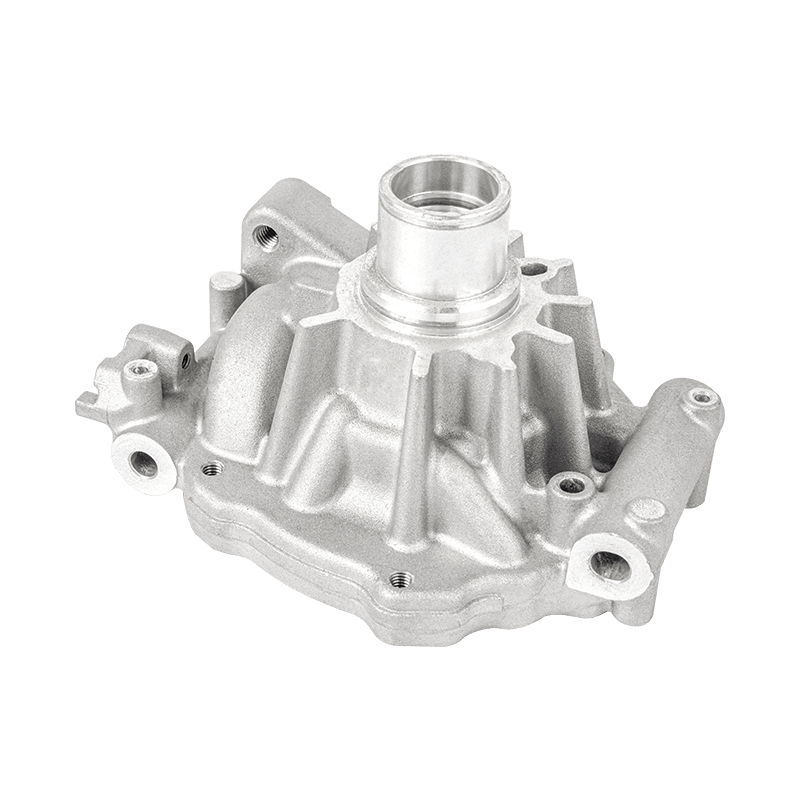

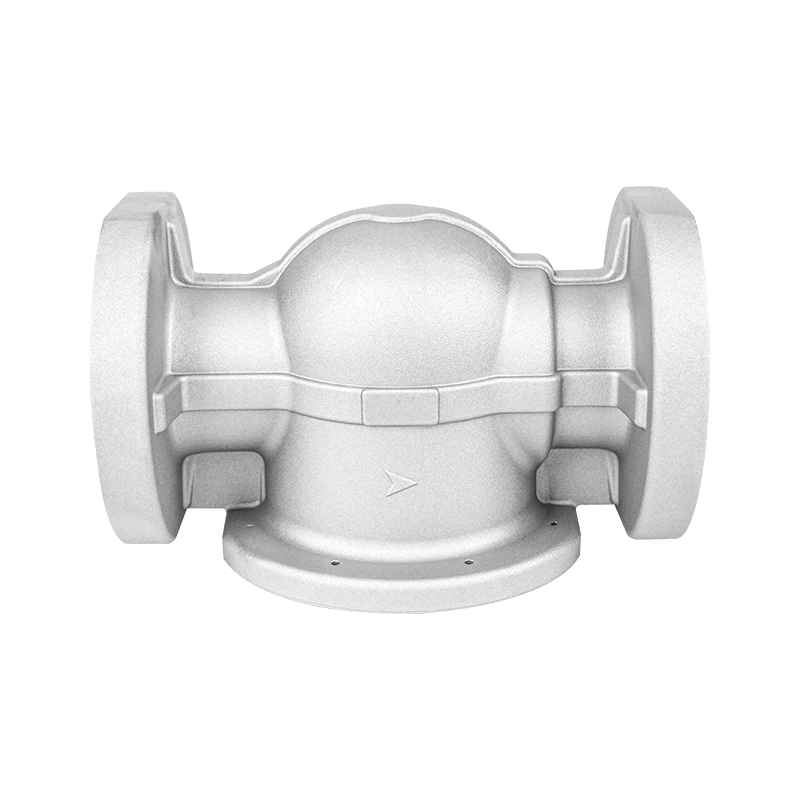

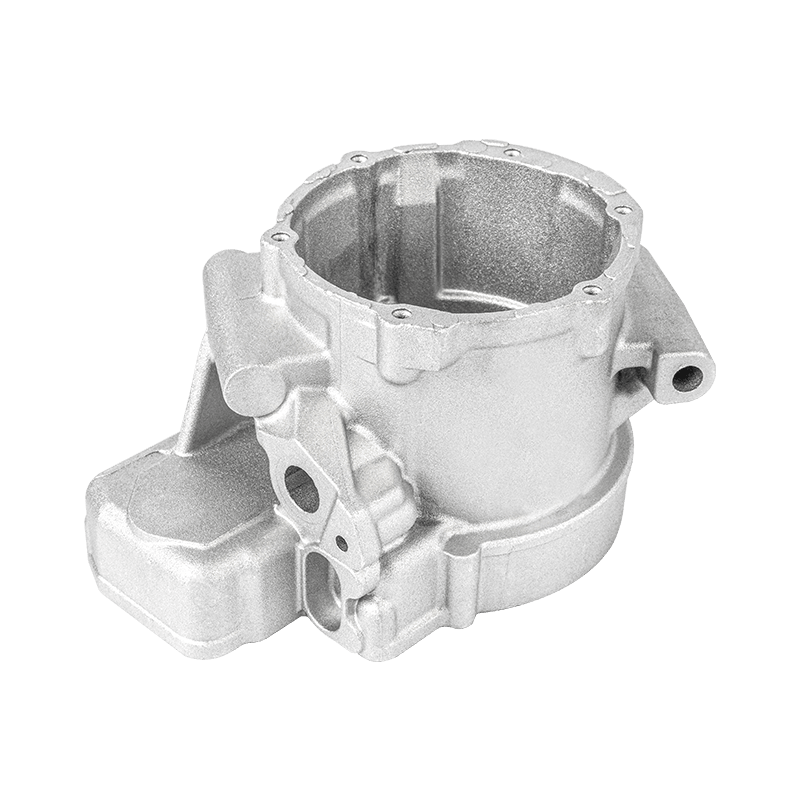

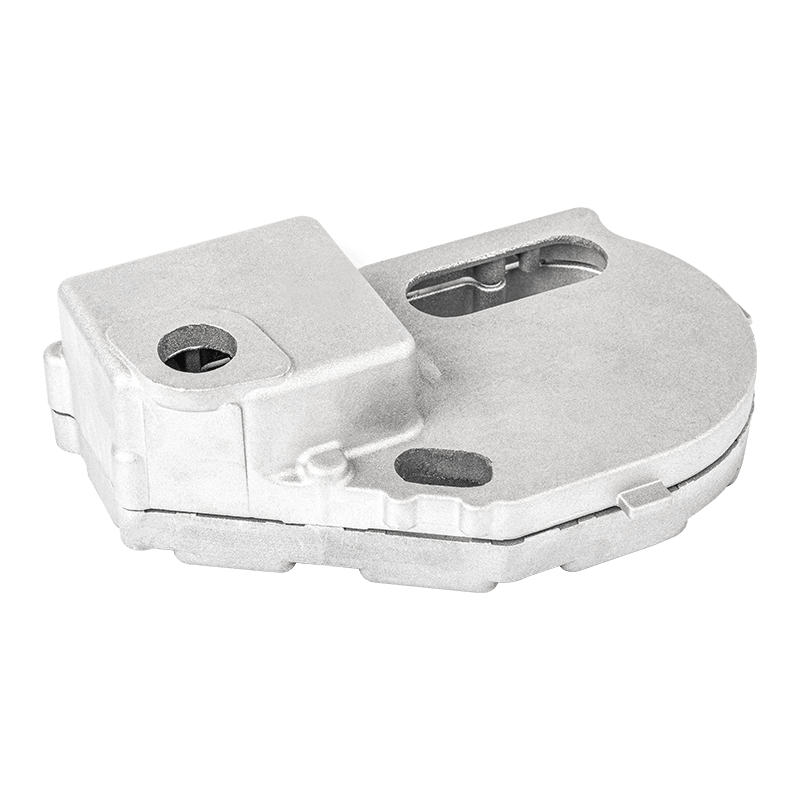

Aluminum die-casting offers several advantages over traditional materials like steel or iron. One of the most significant benefits is its exceptional strength-to-weight ratio. Aluminum is significantly lighter than steel or iron while still providing adequate strength and durability for automotive applications. By utilizing aluminum die-cast parts in electric vehicles, manufacturers can reduce the vehicle's overall weight without sacrificing structural integrity or safety.

The impact of reducing vehicle weight on electric vehicle range cannot be overstated. Electric vehicles rely on onboard batteries to store and supply energy for propulsion, and any reduction in vehicle weight directly translates to improved energy efficiency and extended range. With lighter aluminum components, electric vehicles require less energy to accelerate, maintain speed, and climb hills, resulting in increased range per charge.

Furthermore, the lightweight nature of aluminum die-cast parts enhances the efficiency of regenerative braking systems in electric vehicles. Regenerative braking allows electric vehicles to recover kinetic energy during deceleration and braking, which is then converted back into electrical energy and stored in the battery. Lighter vehicles experience less inertia during braking, allowing them to capture more kinetic energy and increase overall energy regeneration. This not only improves the vehicle's efficiency but also helps extend its range by reducing the amount of energy needed from the battery to maintain operation.

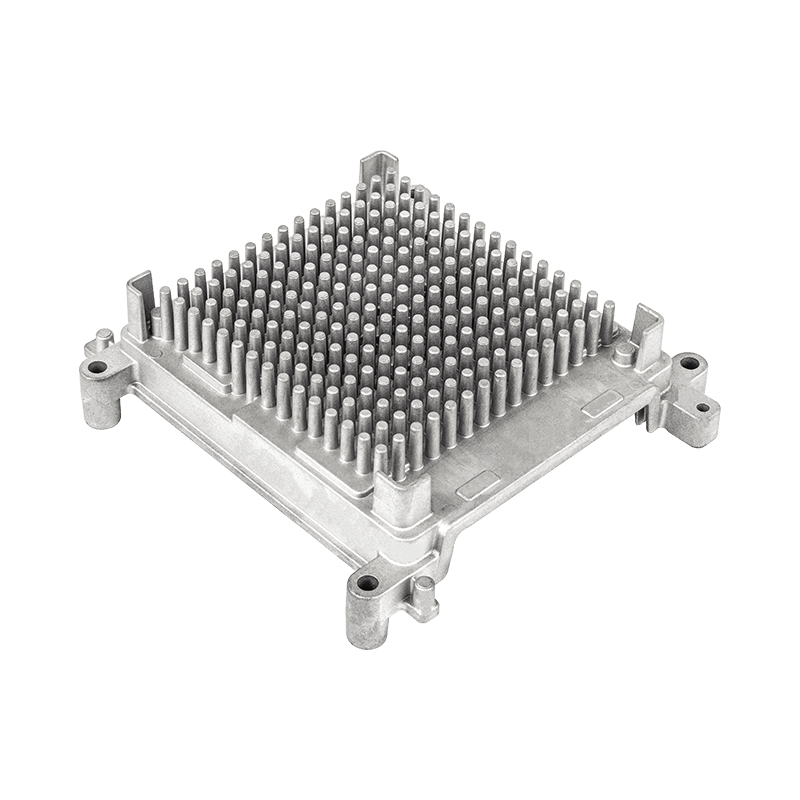

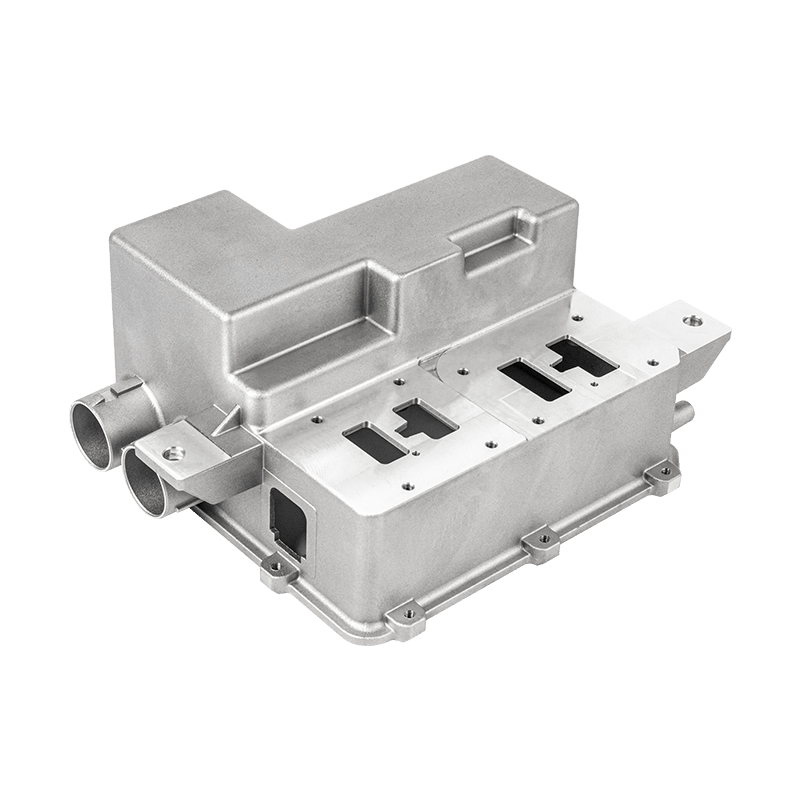

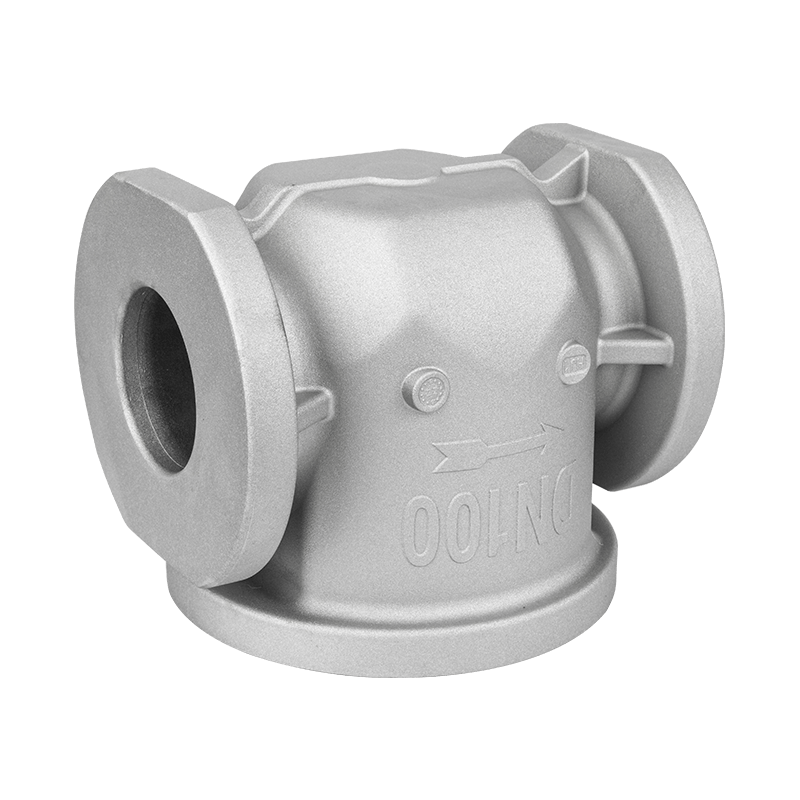

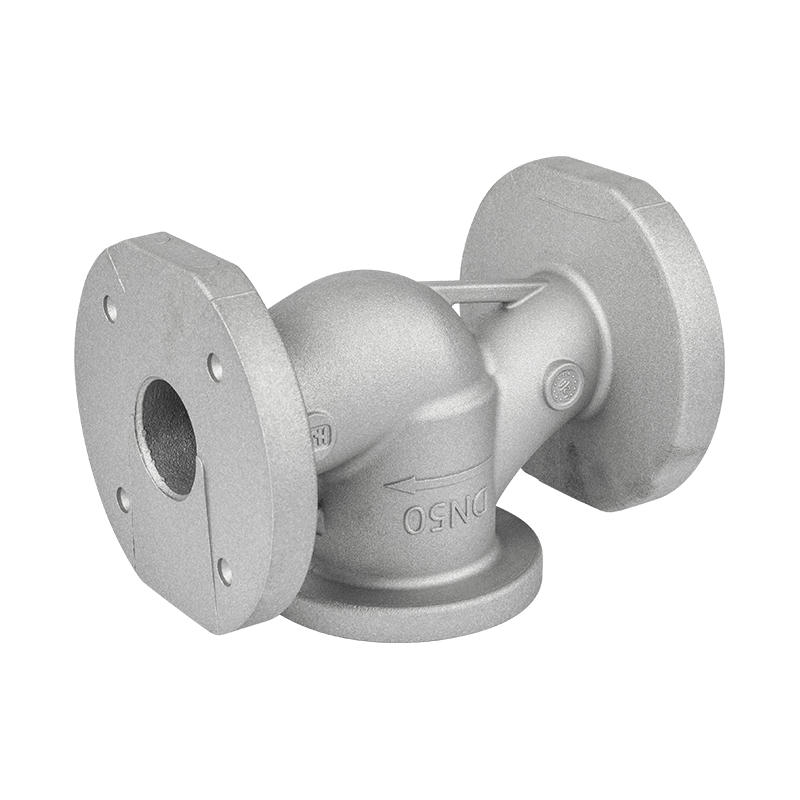

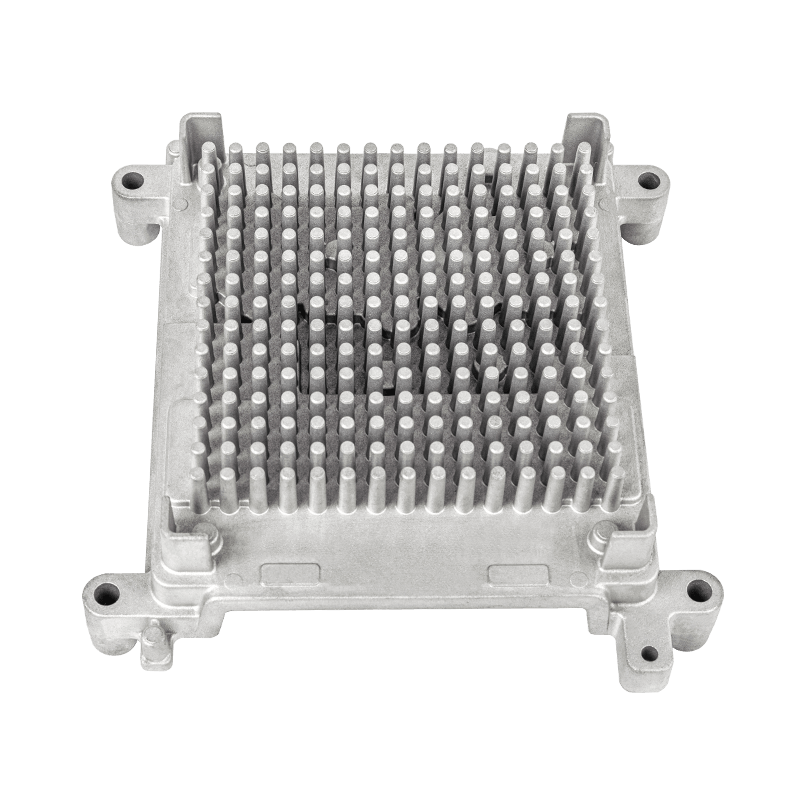

Additionally, the use of aluminum die-cast parts contributes to better thermal management in electric vehicles. Aluminum's excellent thermal conductivity properties help dissipate heat generated by electric motors, batteries, and other vehicle components more efficiently. By maintaining optimal operating temperatures, aluminum components can enhance the performance and longevity of critical vehicle systems, ultimately leading to improved efficiency and range.

Moreover, the lightweight nature of aluminum die-cast parts positively impacts the handling and driving dynamics of electric vehicles. With reduced mass, electric vehicles equipped with aluminum components exhibit better agility, responsiveness, and maneuverability, enhancing the overall driving experience. This improved handling not only makes electric vehicles more enjoyable to drive but also allows drivers to optimize their driving patterns to further maximize range.