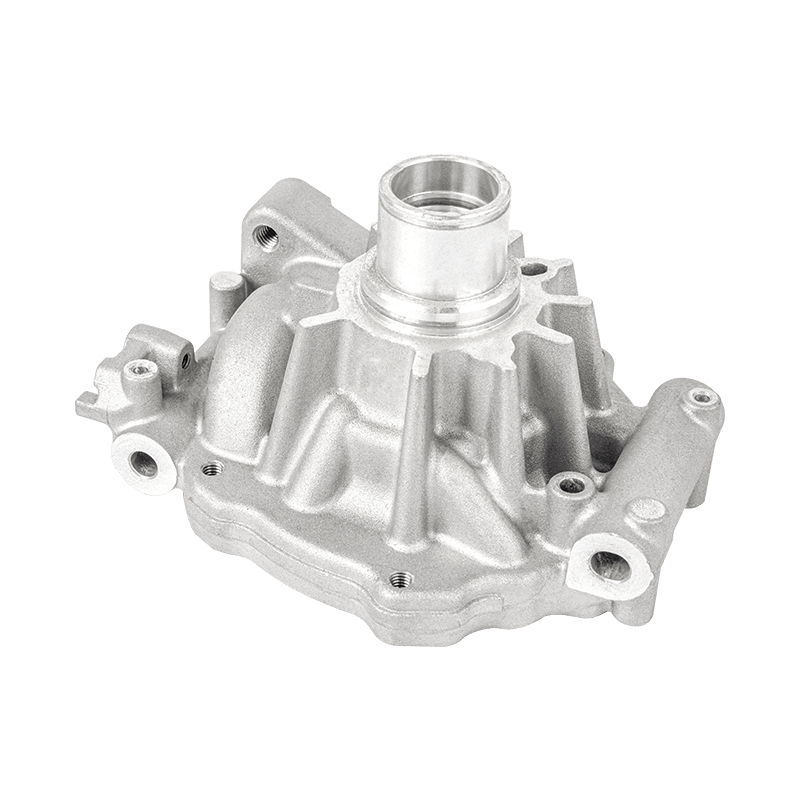

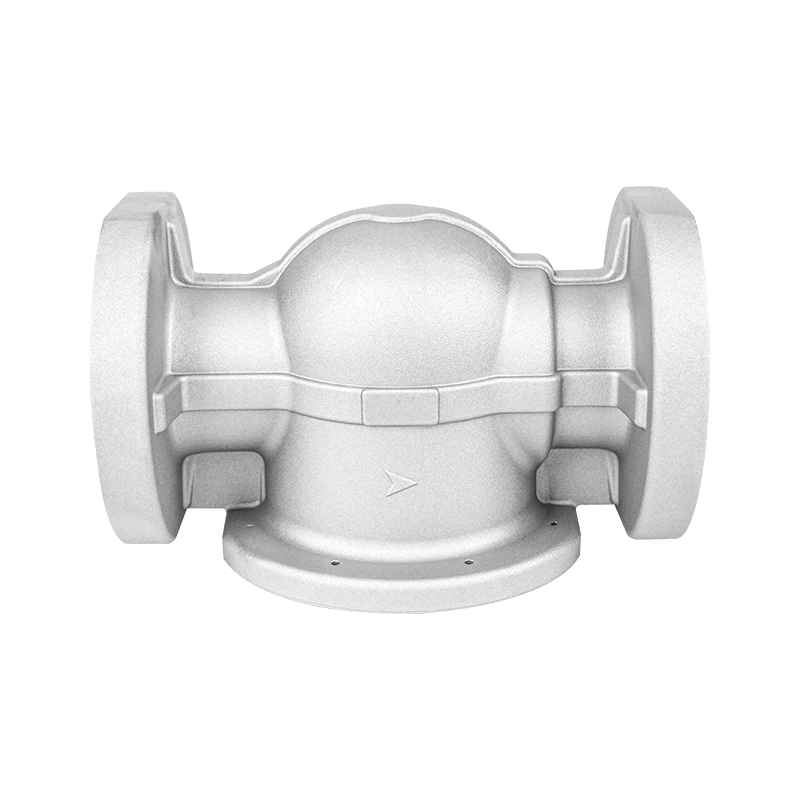

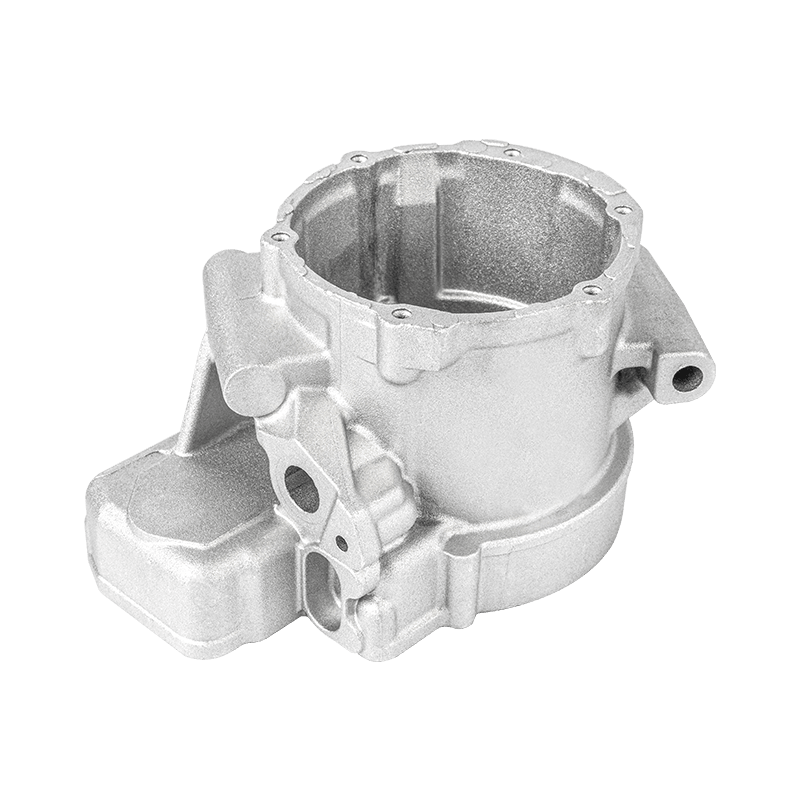

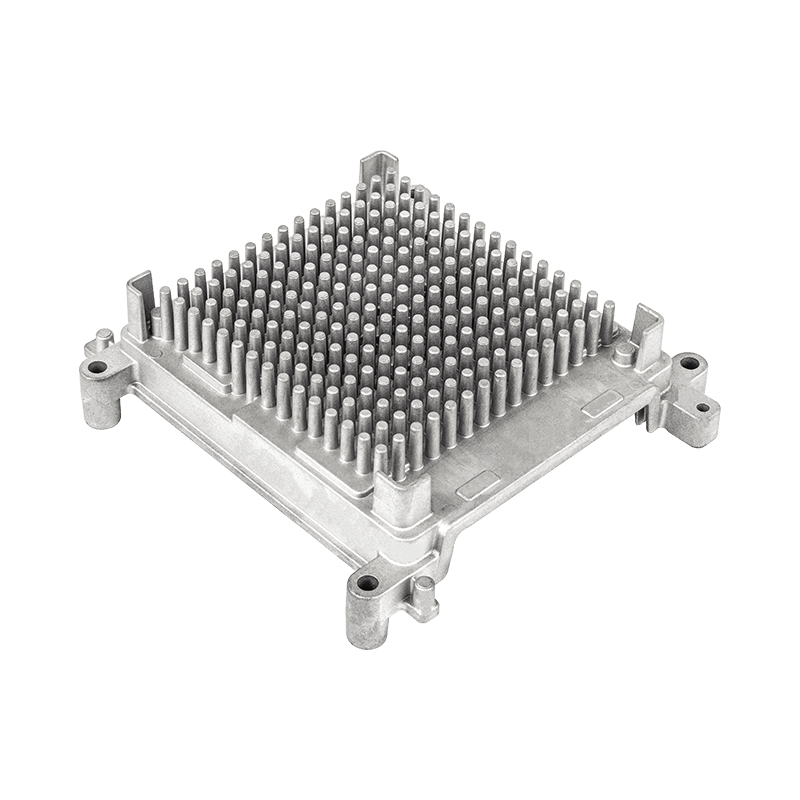

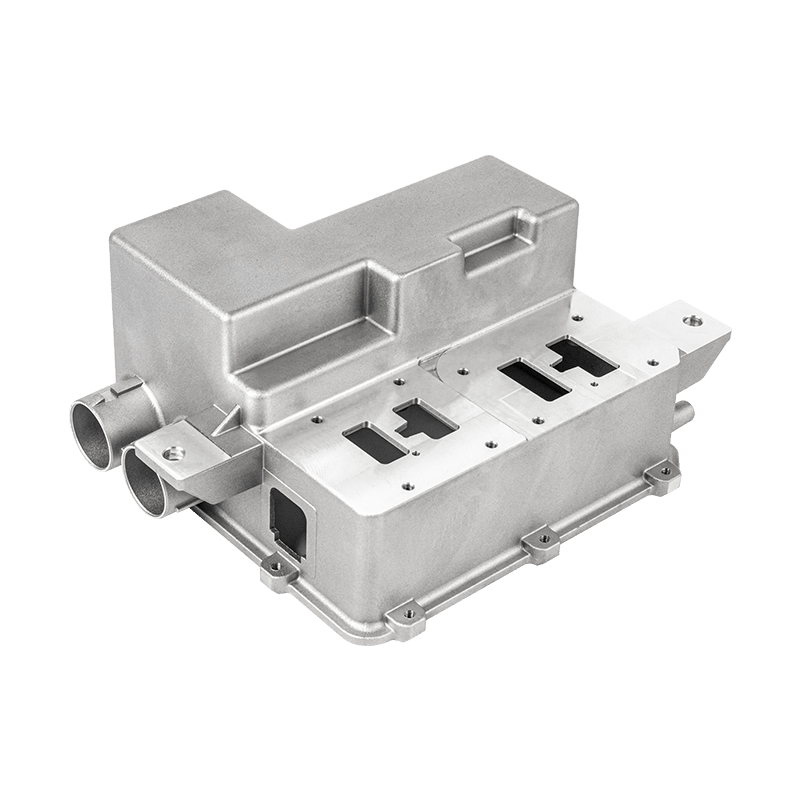

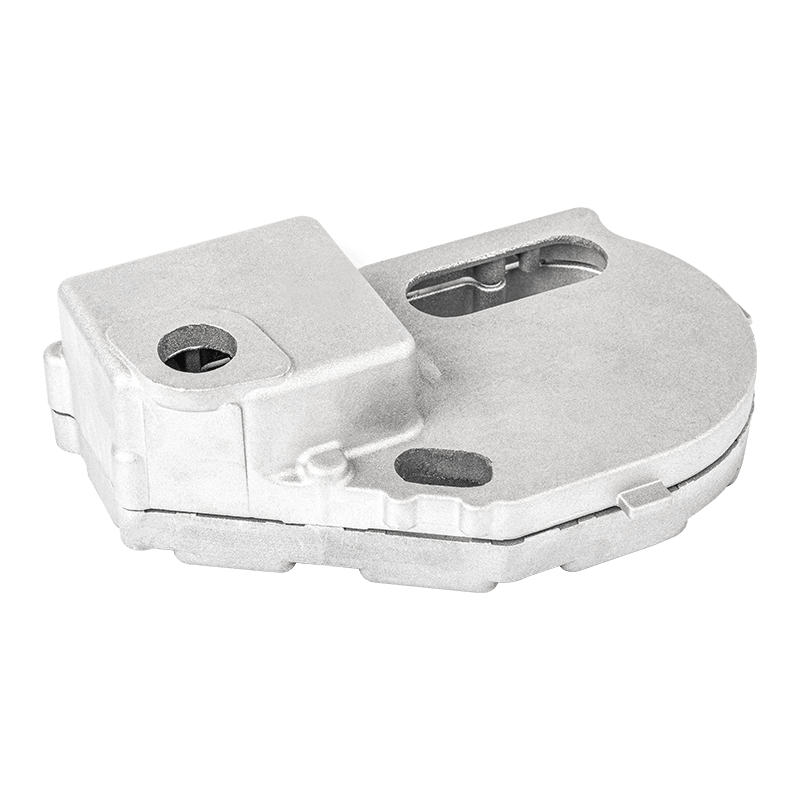

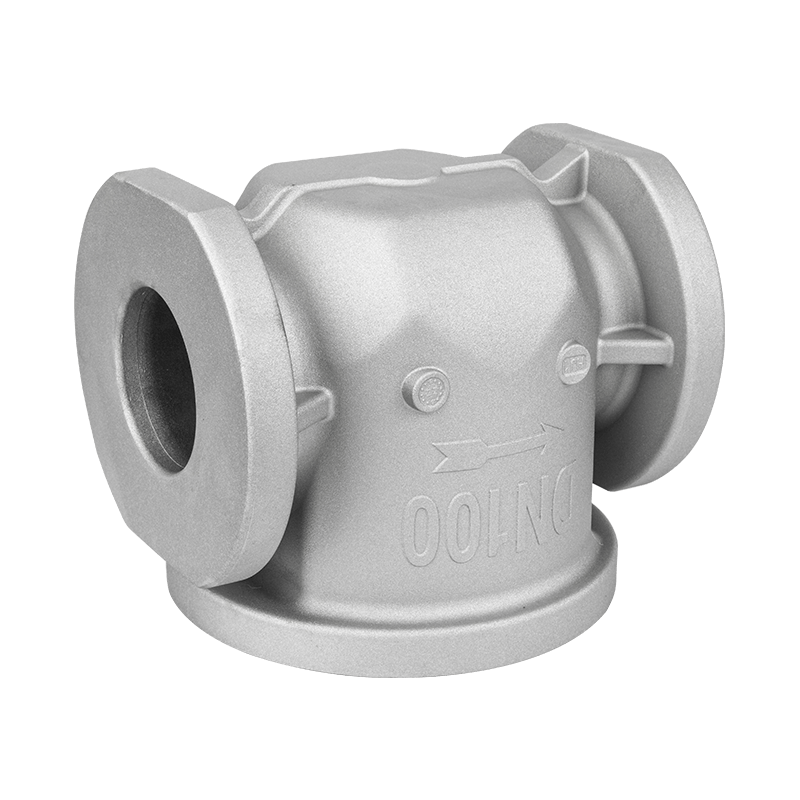

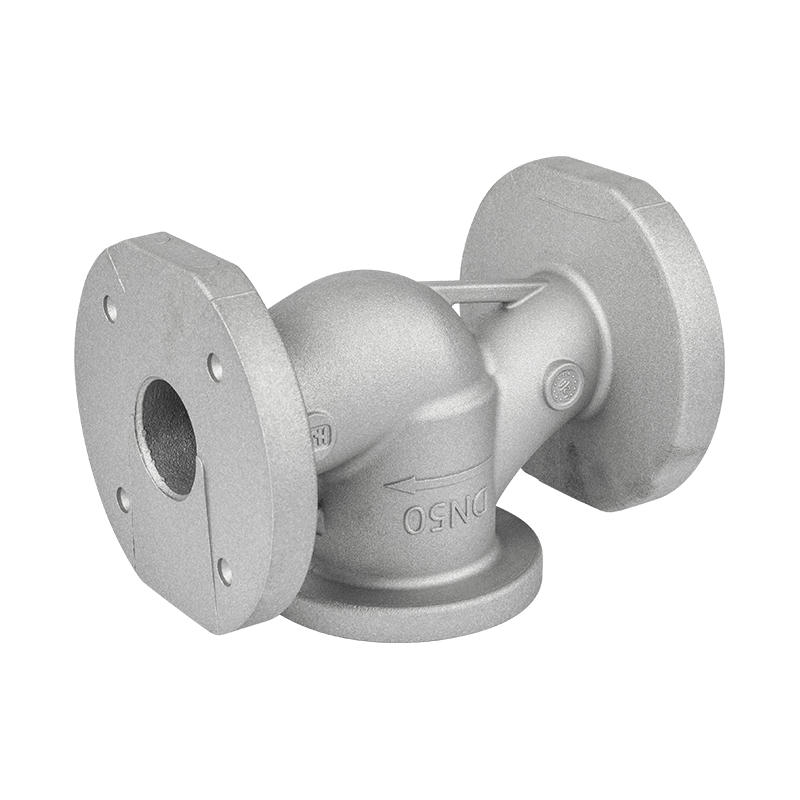

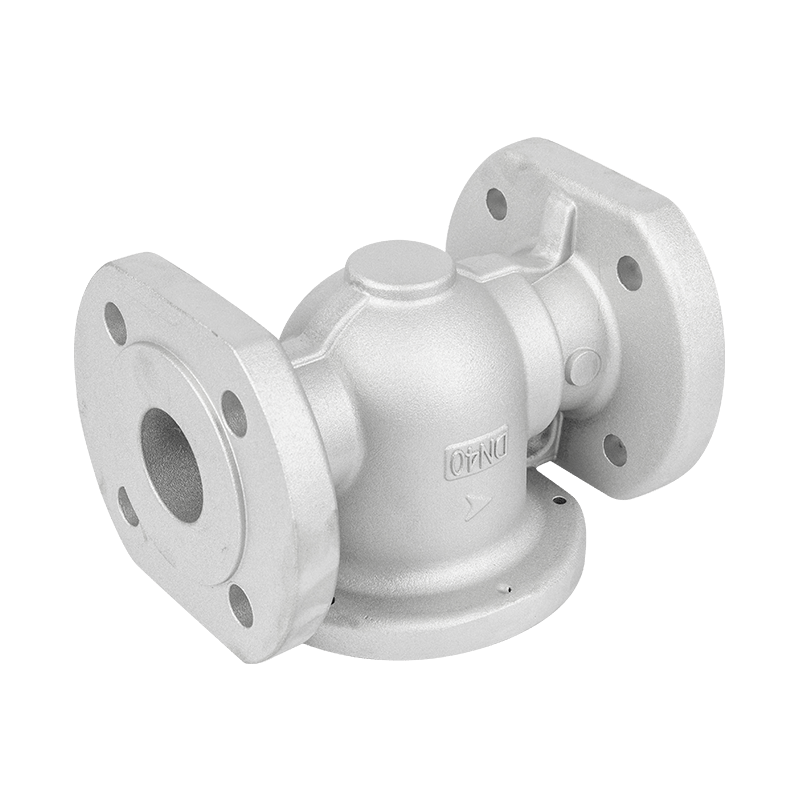

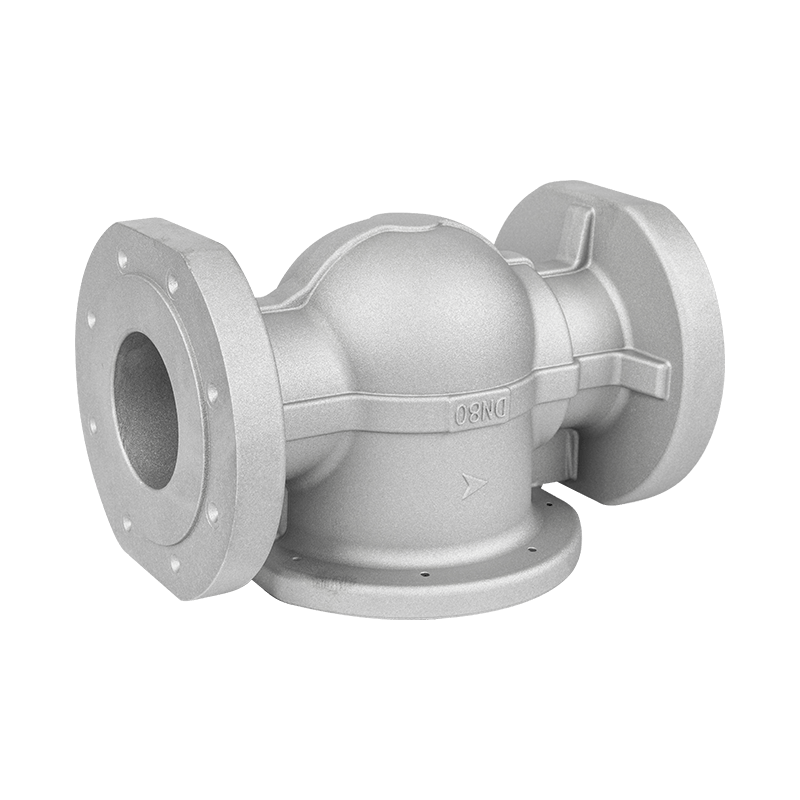

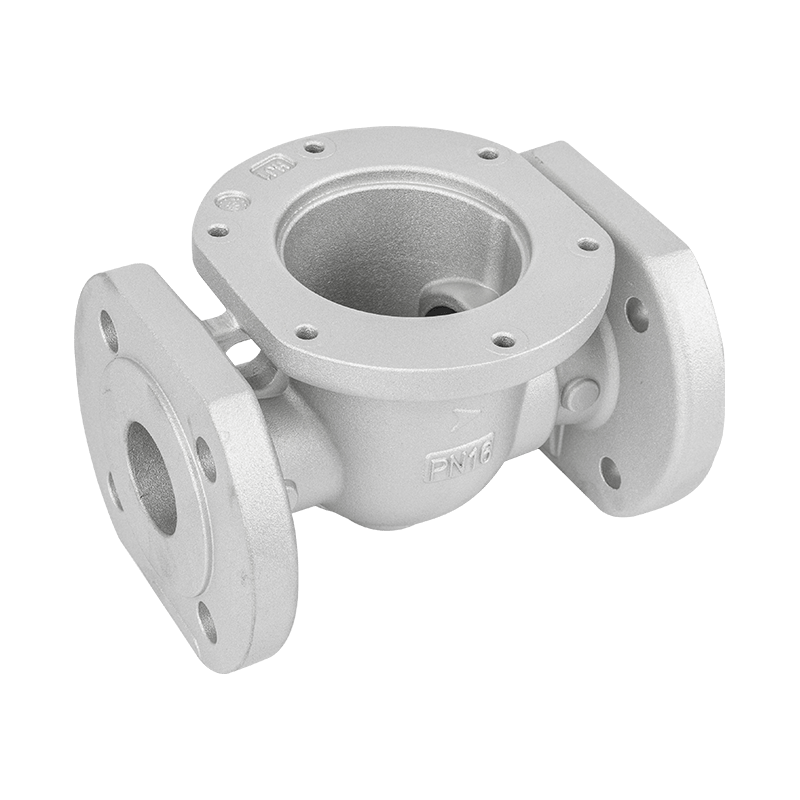

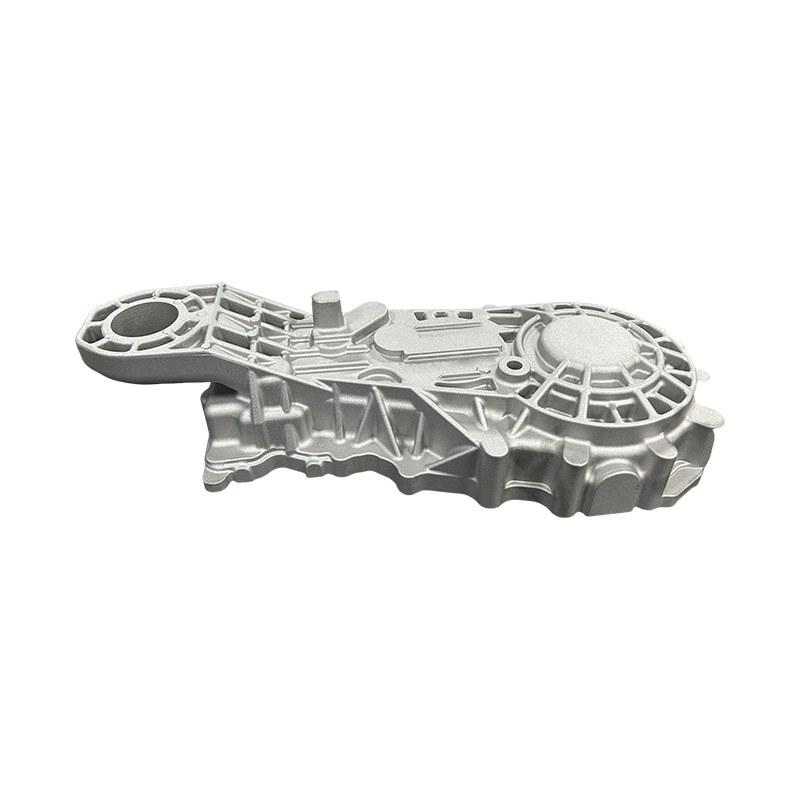

Aluminum die-casting parts are aluminum parts with different functions, which are processed by molds of different shapes. Its quality determines whether other equipment can operate normally, then how to see whether it is a qualified product and how to test it. Don't worry, the following is an introduction to the inspection specifications for aluminum die castings. I hope these instructions will give you an idea of what kind of aluminum parts are qualified.

1. It must be a complete individual. There should be no defects such as defects, cracks, bubbles, etc., and there should be no mold phenomenon.

2. The gate and flashing parts of the casting should be wiped frequently and kept clean at all times.

3. Defects that cannot appear on the processed surface are mixed with impurities, and the pores are sparse.

4. The level of the machining mark on the top of the aluminum part should not exceed 0.2 mm.