Several industries benefit significantly from the use of aluminium pressure die casting products due to the versatility, durability, and cost-effectiveness of this manufacturing process. Here are some industries that particularly benefit:

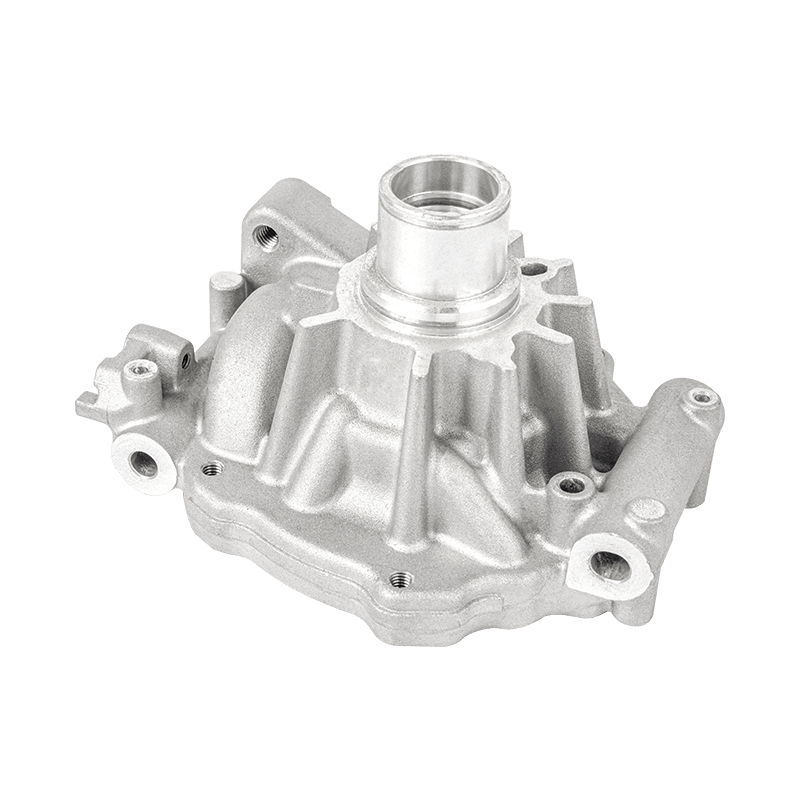

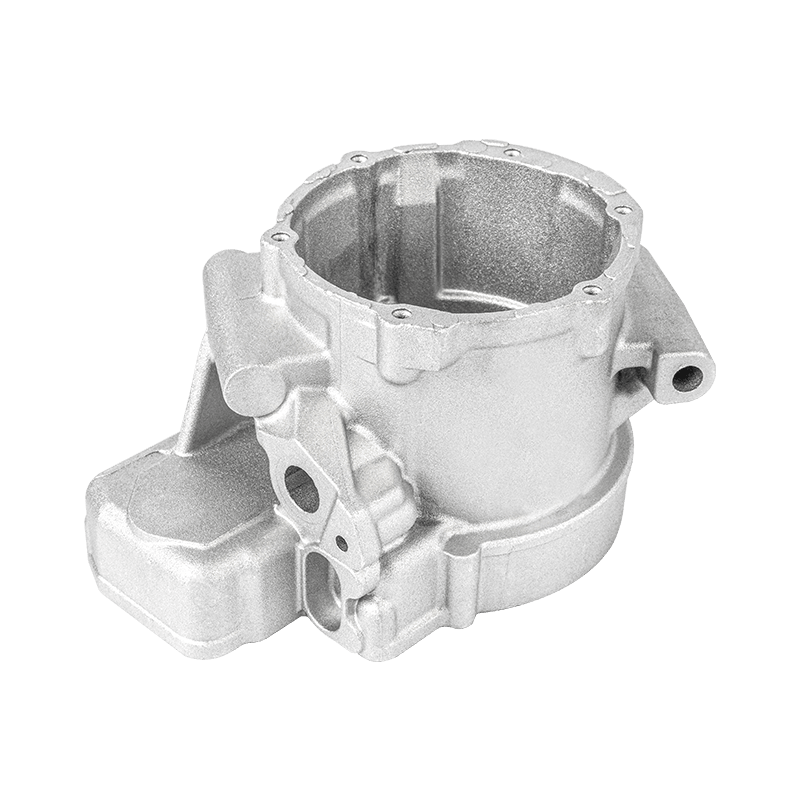

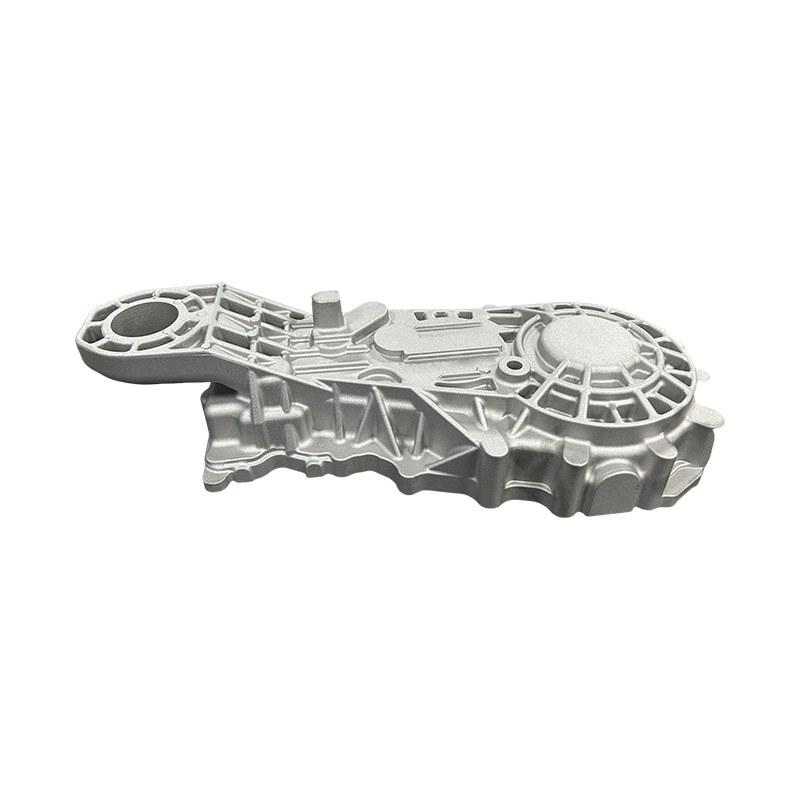

Automotive Industry: Aluminium pressure die casting products are extensively used in the automotive sector for manufacturing components such as engine blocks, transmission housings, suspension parts, and wheels. The lightweight yet strong nature of aluminium makes it ideal for improving fuel efficiency and performance in vehicles.

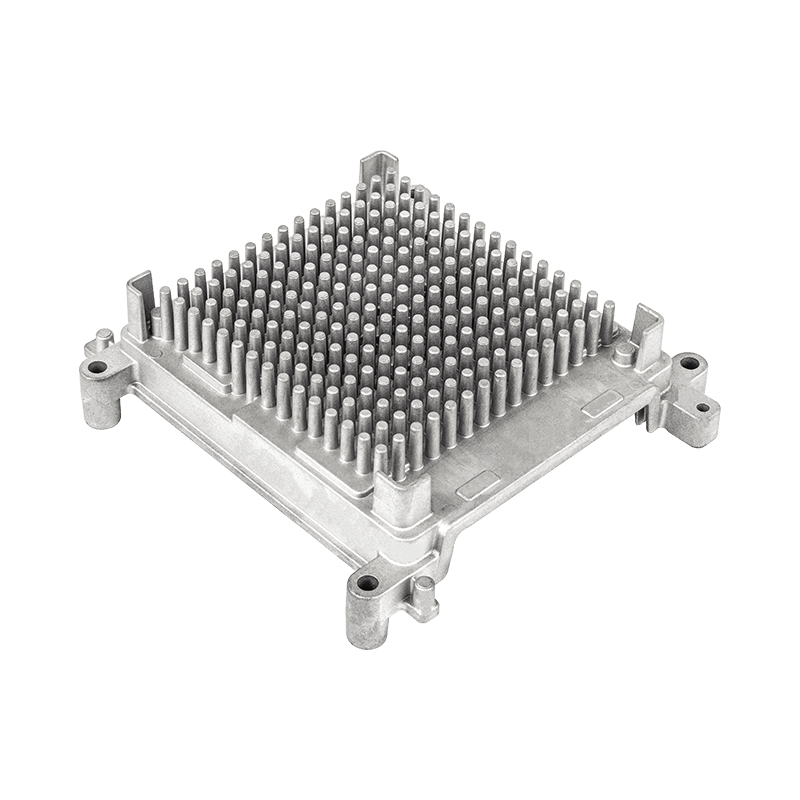

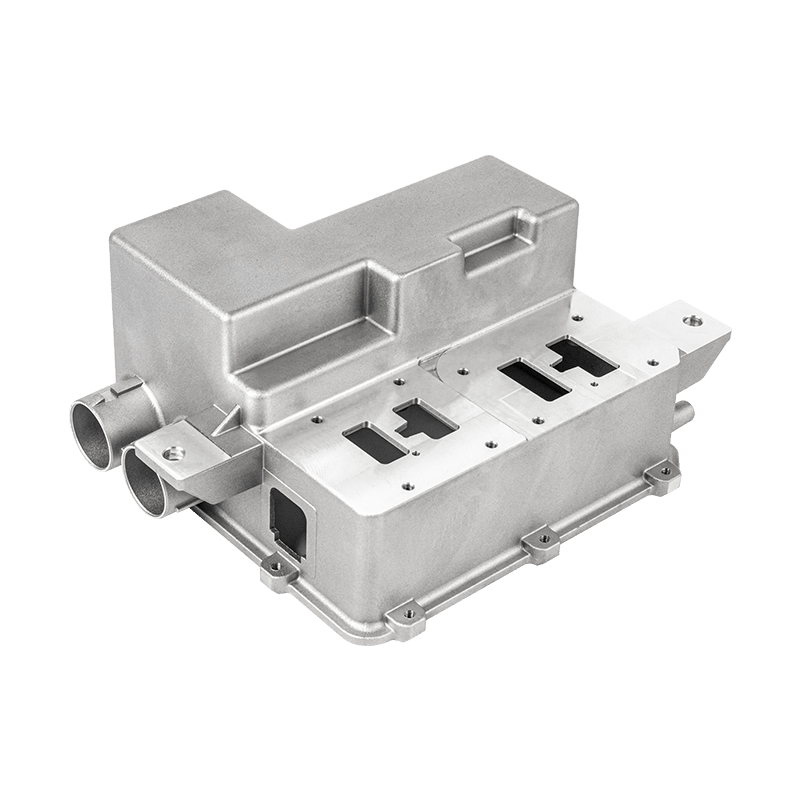

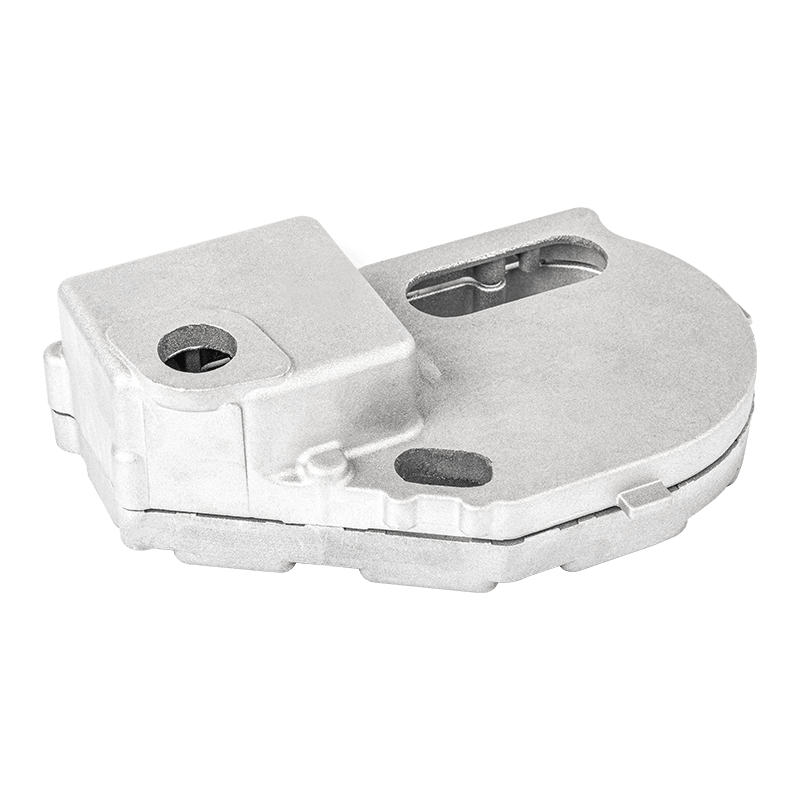

Electronics and Electrical: The electronics and electrical industry utilize aluminium pressure die casting products for manufacturing components like heat sinks, housings for electronic devices, connectors, and LED lighting fixtures. Aluminium's excellent thermal conductivity and electrical properties make it an ideal choice for these applications.

Consumer Goods: Various consumer goods industries, including home appliances, sporting goods, and furniture, benefit from aluminium pressure die casting products. Items such as kitchen appliances, power tools, bicycles, and furniture hardware often incorporate die-cast aluminium components due to their lightweight, durable, and aesthetically pleasing qualities.

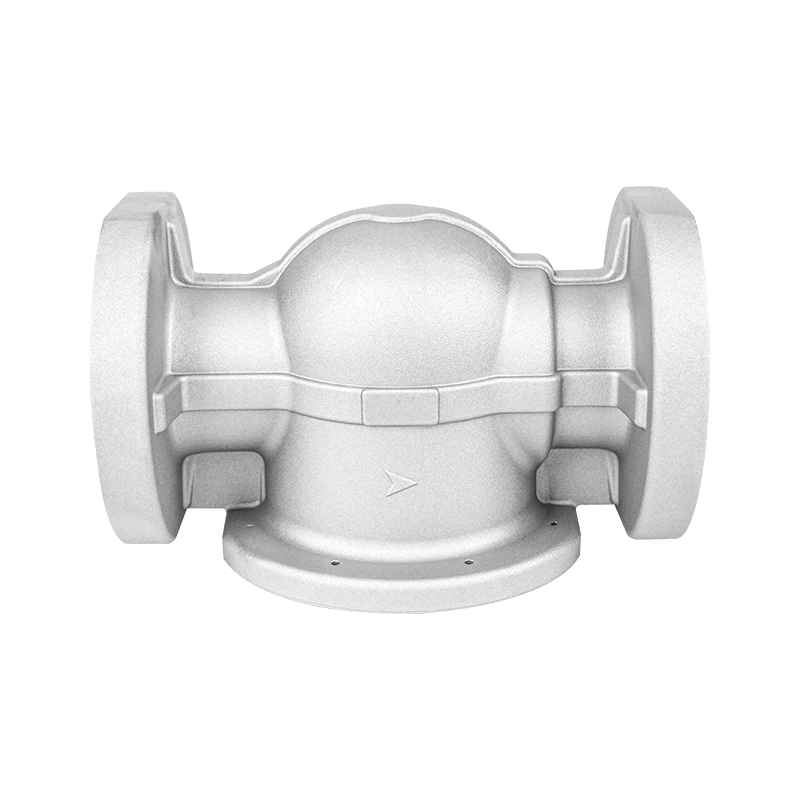

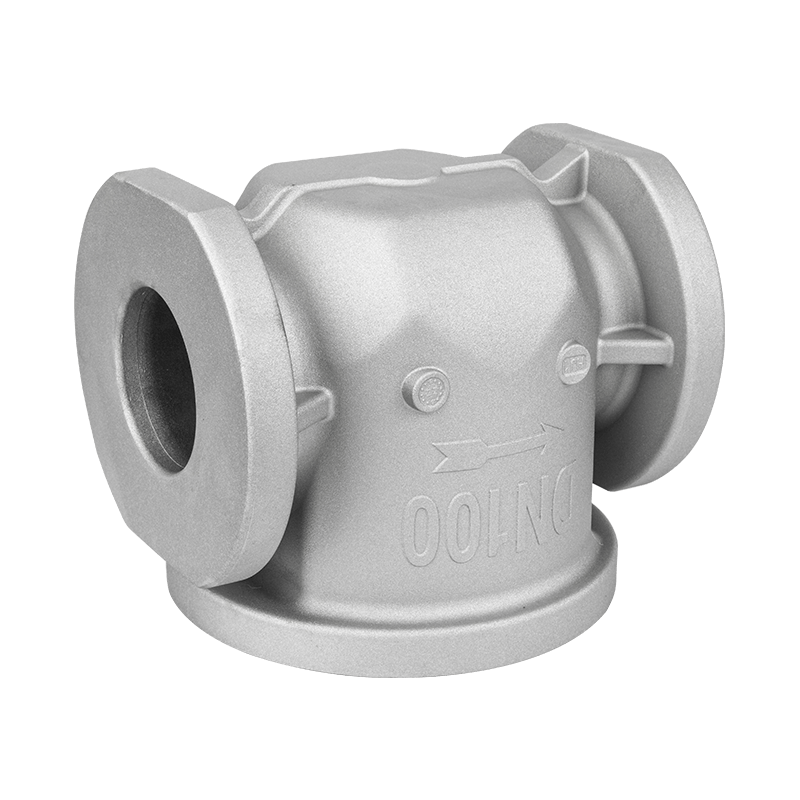

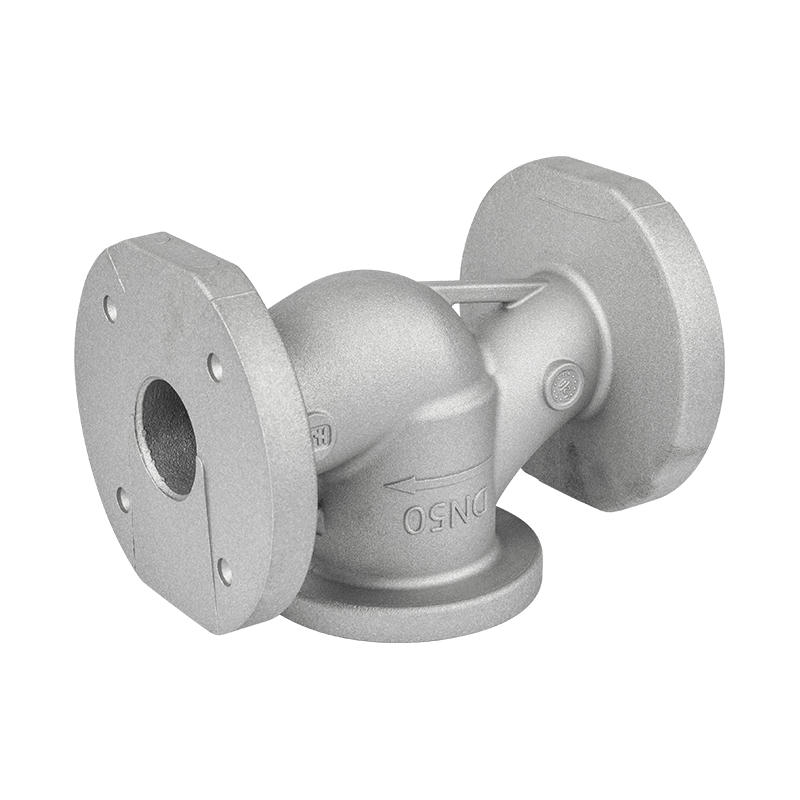

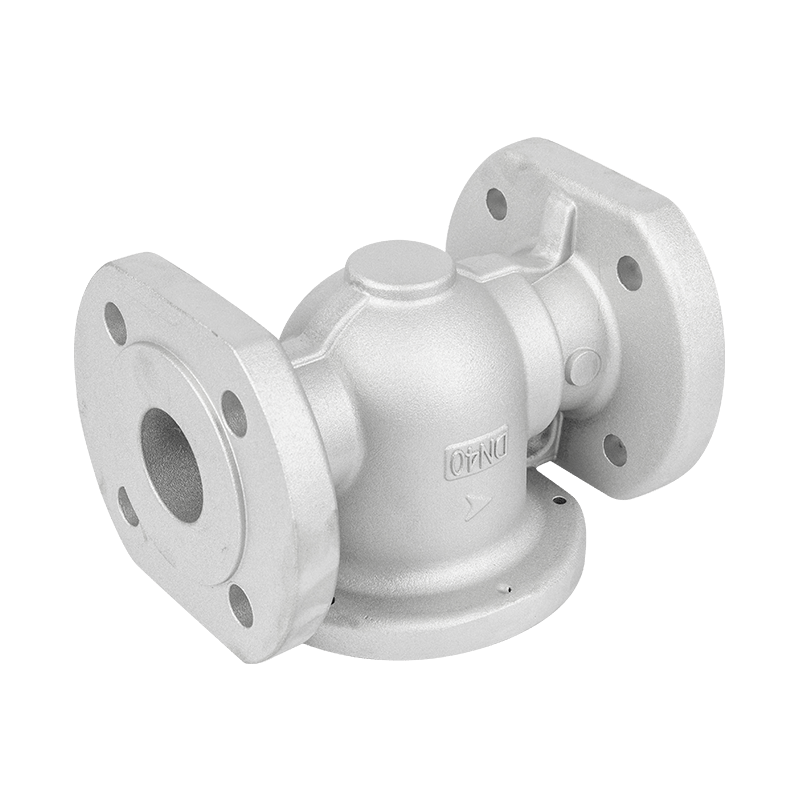

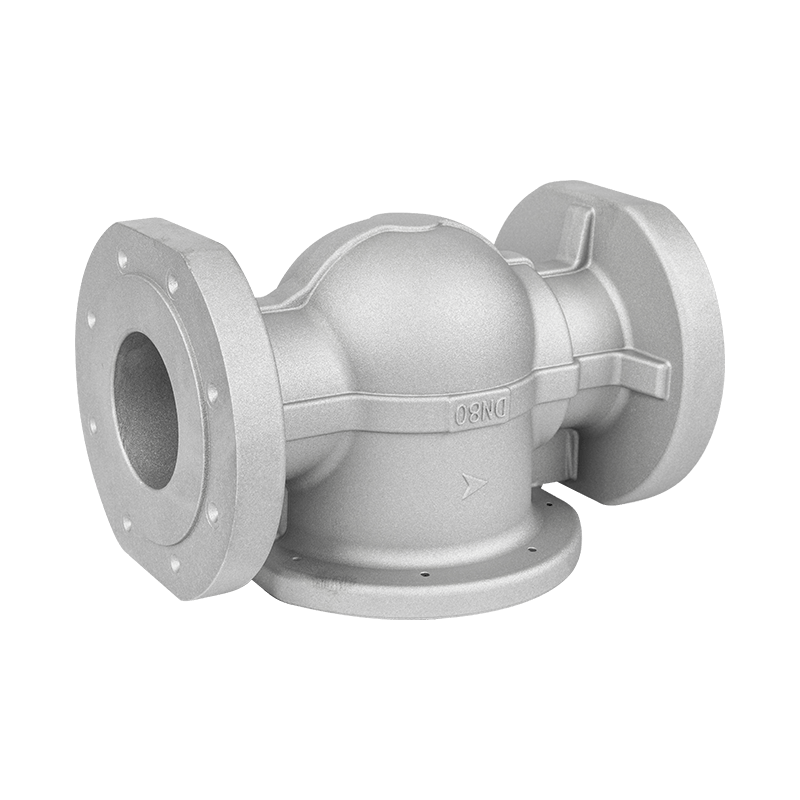

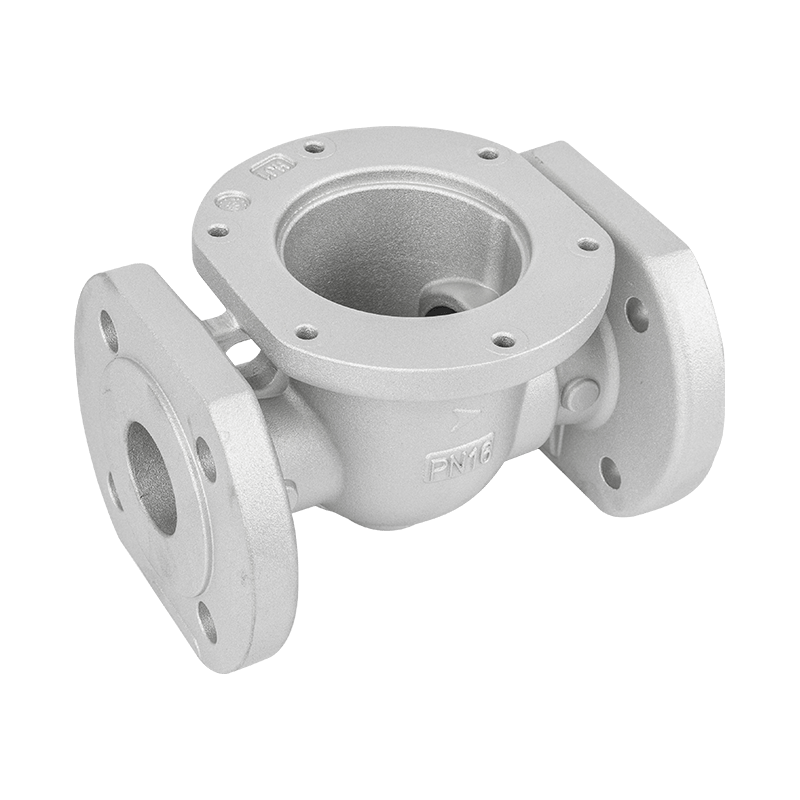

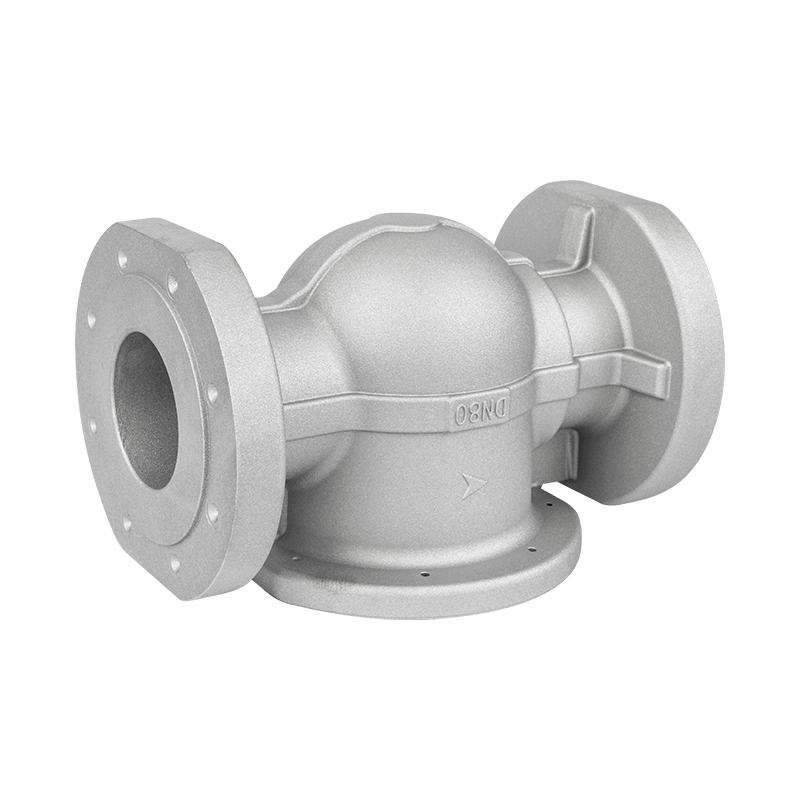

Industrial Equipment: Industries that produce heavy machinery, industrial equipment, and tools utilize aluminium pressure die casting products for parts like pump housings, valve bodies, compressor components, and hydraulic system parts. Aluminium's strength-to-weight ratio and corrosion resistance make it suitable for demanding industrial applications.

Aerospace and Aviation: The aerospace and aviation industries rely on aluminium pressure die casting products for manufacturing aircraft components such as structural parts, engine components, landing gear, and interior fittings. Aluminium's lightweight properties are essential for reducing aircraft weight and improving fuel efficiency.

Telecommunications: In the telecommunications industry, aluminium pressure die casting products are used for manufacturing components like antenna housings, satellite dish brackets, and telecommunications infrastructure. Aluminium's durability, corrosion resistance, and ability to withstand harsh environmental conditions make it an ideal material for these applications.

Renewable Energy: The renewable energy sector benefits from aluminium pressure die casting products for manufacturing components used in solar panels, wind turbines, and other renewable energy systems. Aluminium's lightweight and corrosion-resistant properties contribute to the efficiency and longevity of renewable energy infrastructure.

Medical Devices: Medical device manufacturers utilize aluminium pressure die casting products for producing components such as surgical instruments, imaging equipment, and patient monitoring devices. Aluminium's biocompatibility, sterilizability, and precision manufacturing capabilities make it suitable for medical applications.

These industries and many others leverage the advantages of aluminium pressure die casting products to manufacture high-quality, durable, and cost-effective components for a wide range of applications.