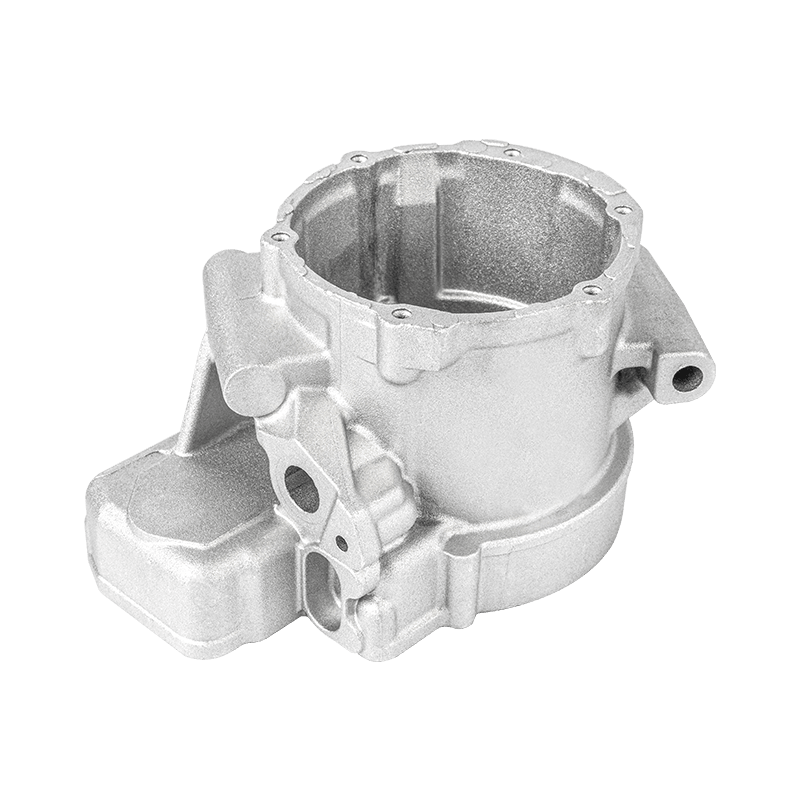

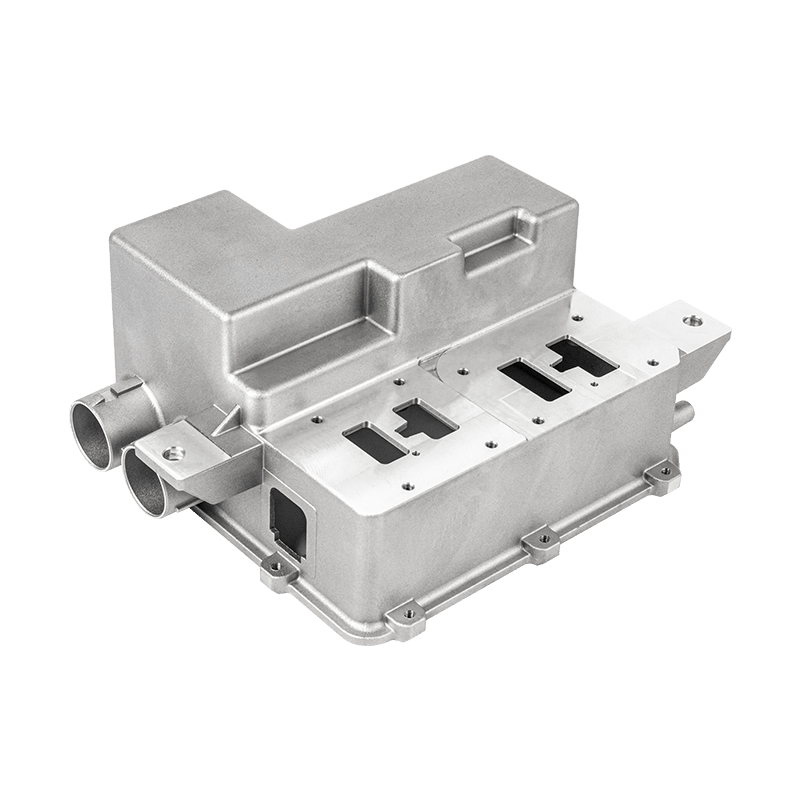

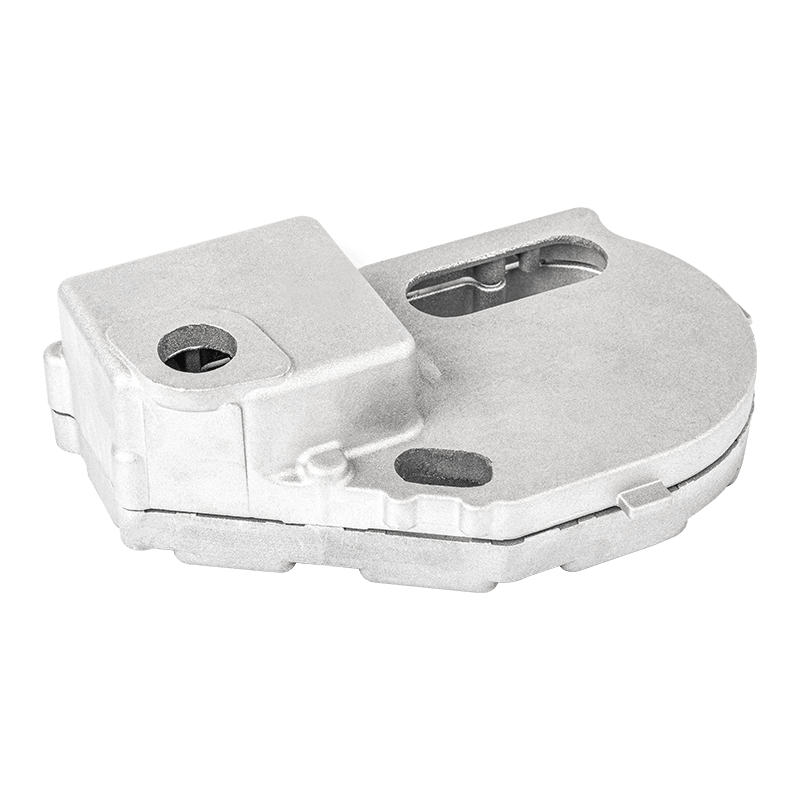

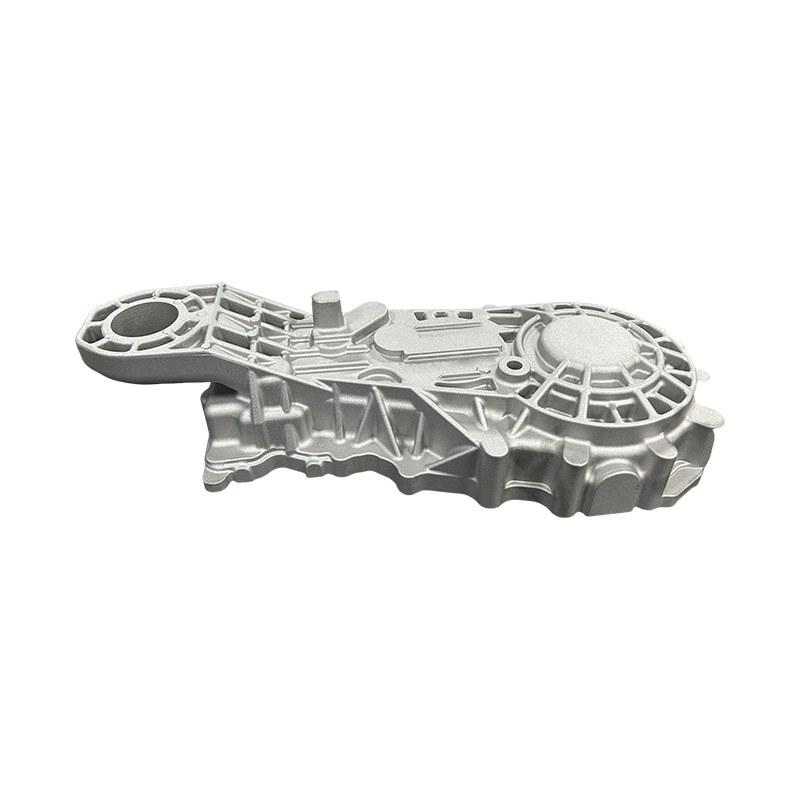

Aluminum die-casting is the preferred method for producing high-quality 48V DCDC converter housing in auto parts due to its unique combination of properties and manufacturing advantages.

Firstly, aluminum is lightweight yet durable, making it an ideal material for automotive applications where weight reduction is crucial for improving fuel efficiency and overall vehicle performance. Despite its lightweight nature, aluminum provides sufficient strength and structural integrity required to protect sensitive electronic components like the 48V DCDC converter.

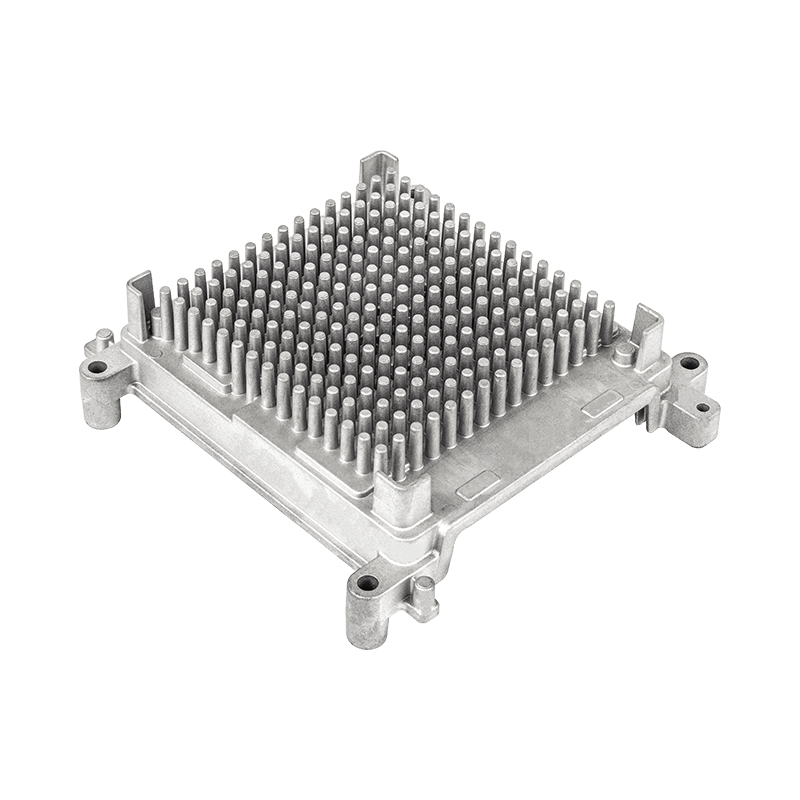

Moreover, aluminum boasts excellent thermal conductivity, allowing it to efficiently dissipate heat generated by electronic components. This is particularly important for components like the DCDC converter, which may produce significant amounts of heat during operation. Effective heat dissipation helps maintain optimal operating temperatures, ensuring the longevity and reliability of the converter.

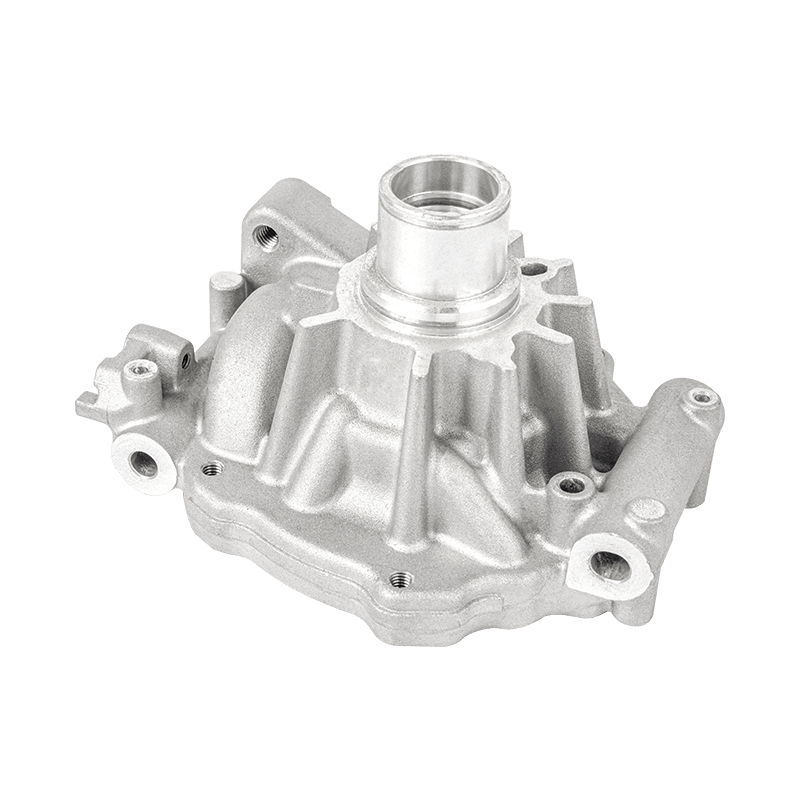

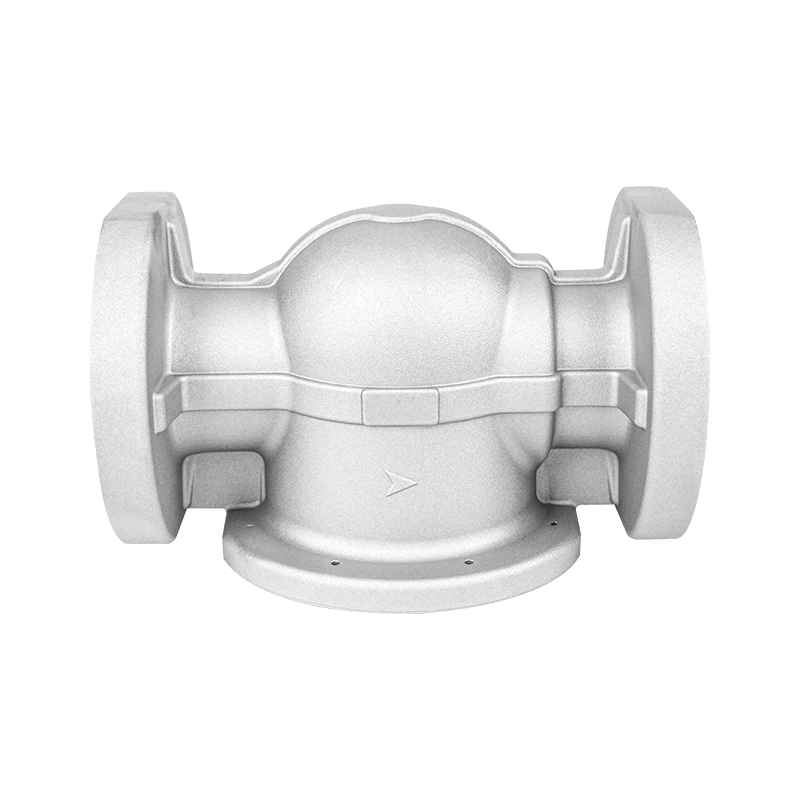

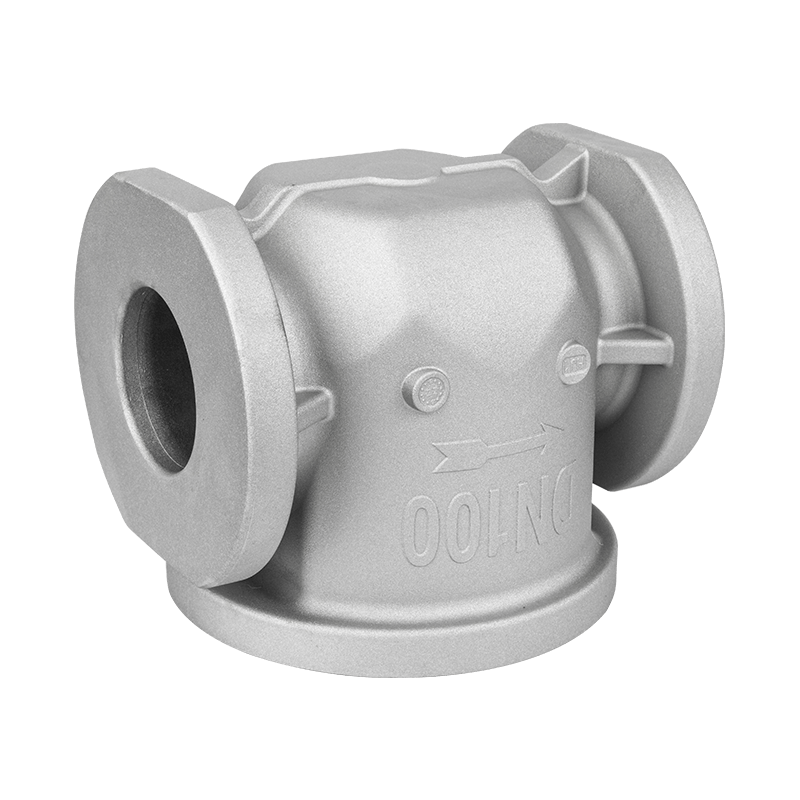

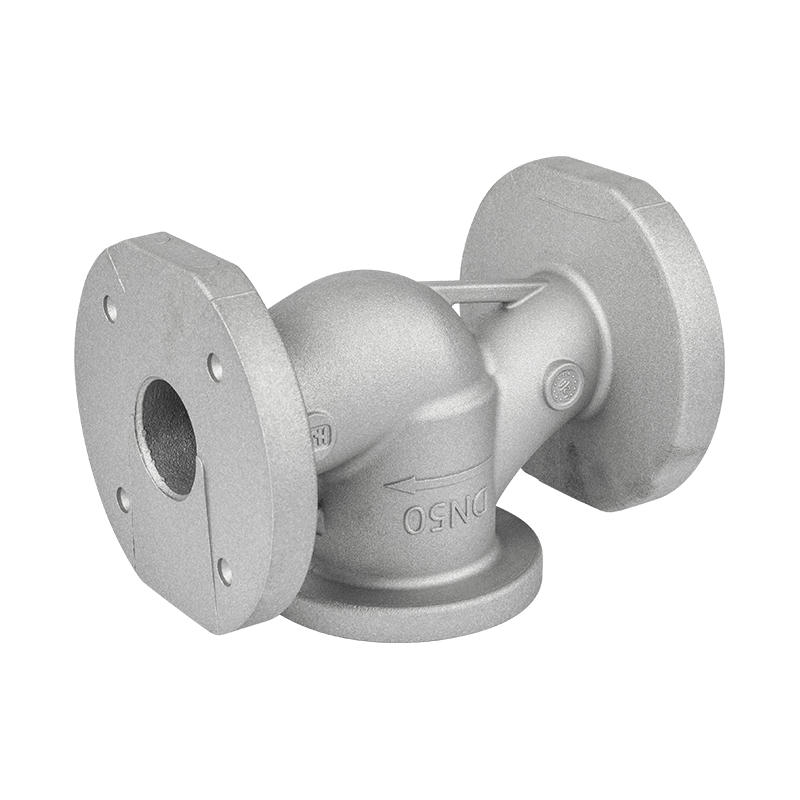

The aluminum die-casting process offers several manufacturing advantages that further enhance its suitability for producing 48V DCDC converter housing. One key advantage is the ability to create complex and intricate shapes with high precision. This flexibility in design allows engineers to optimize the housing's geometry to accommodate various electronic circuits and components within a compact space, maximizing functionality and performance.

Additionally, aluminum die-casting is a cost-effective manufacturing method for producing large quantities of parts with consistent quality. The process enables rapid production cycles and minimizes material wastage, resulting in lower production costs compared to alternative manufacturing methods.

Aluminum's inherent corrosion resistance is another significant benefit for automotive applications. The formation of a protective oxide layer on its surface helps prevent corrosion, ensuring the longevity and reliability of the 48V DCDC converter housing, even in harsh environmental conditions.

Furthermore, aluminum is highly recyclable, aligning with sustainability goals in the automotive industry. Using aluminum die-casting for 48V DCDC converter housing reduces the environmental impact associated with raw material extraction and production, making it a more eco-friendly choice.

Overall, aluminum die-casting offers a combination of lightweight, durability, thermal conductivity, design flexibility, cost-effectiveness, corrosion resistance, and recyclability that makes it the preferred choice for producing high-quality 48V DCDC converter housing in auto parts. These properties ensure the reliability, performance, and sustainability of automotive electronic systems in modern vehicles.