1. Die-casting process and common sense of die-casting aluminum alloy materials...

More Than 10 Years Experience On Aluminum Die Casting

Compliance With Standards IATF16949

APQP Production Process

Strong Technical R&D Capability

Annual Sales Exceed 260 Million

Covers Area 26685 m2, Building Area 31000 m2

Pressure aluminum die-casting

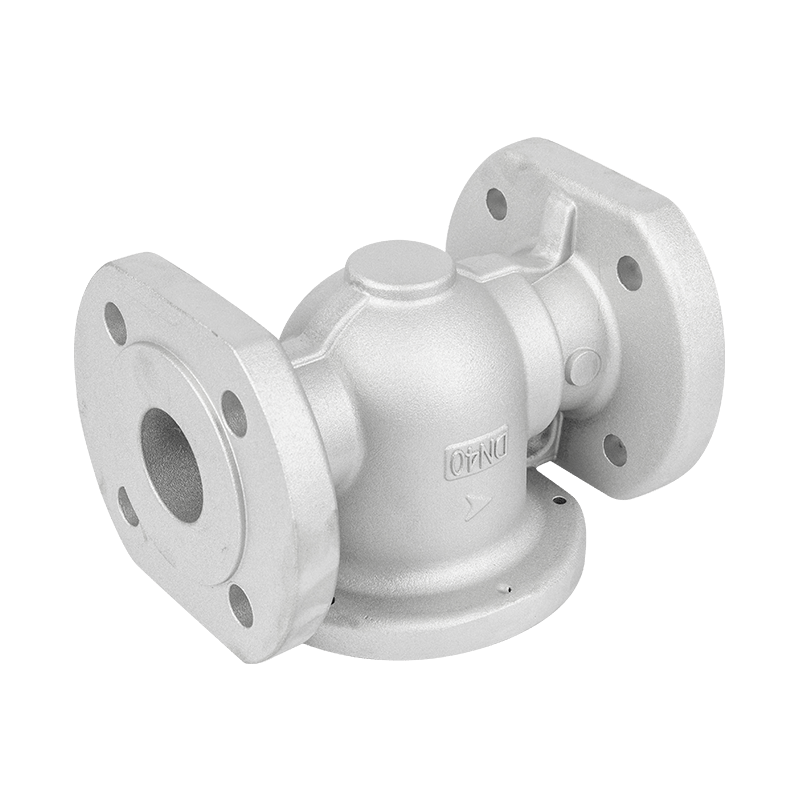

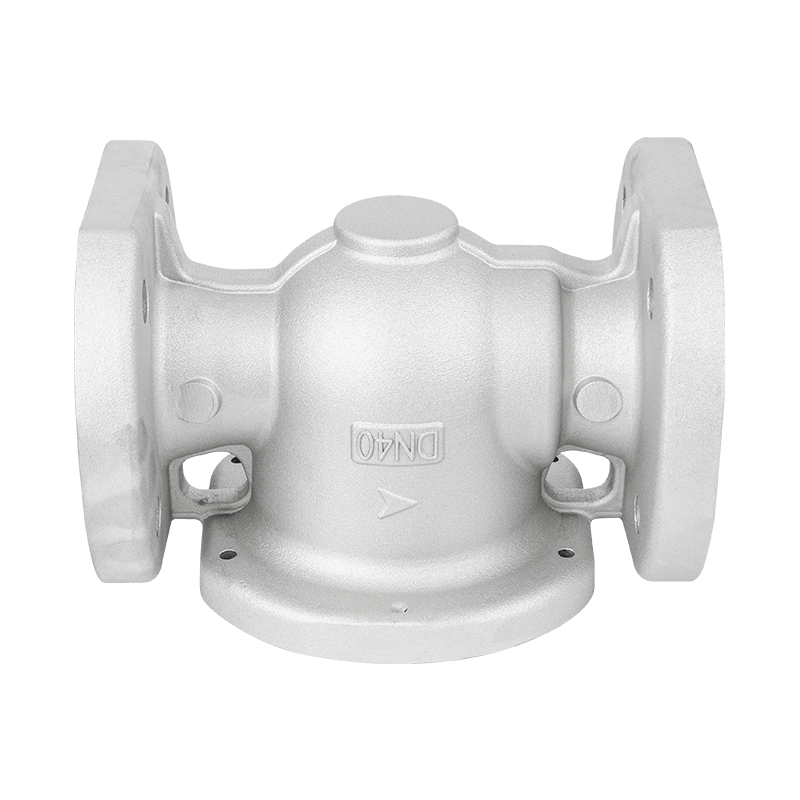

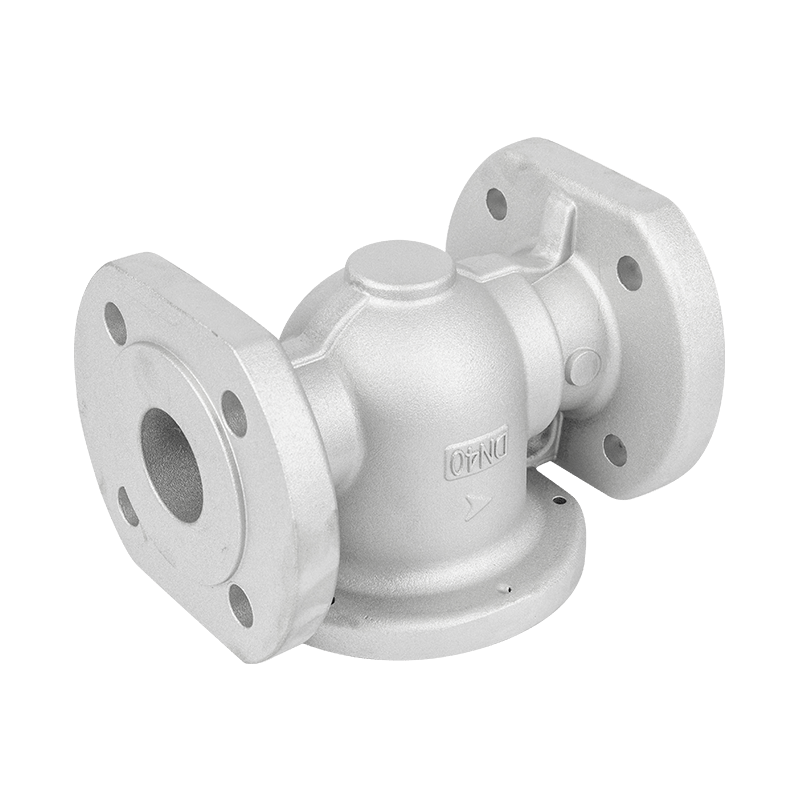

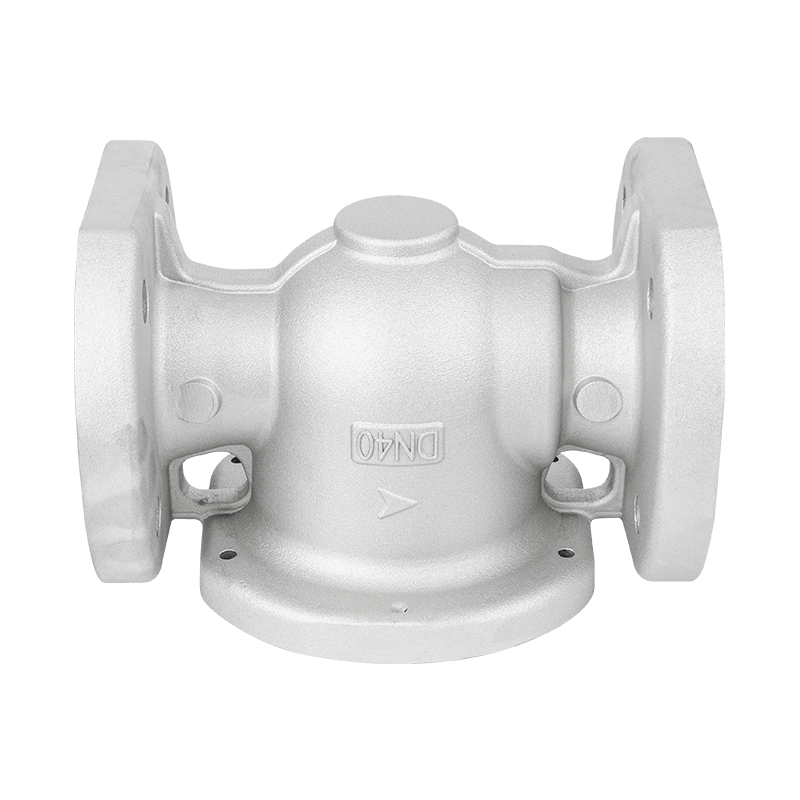

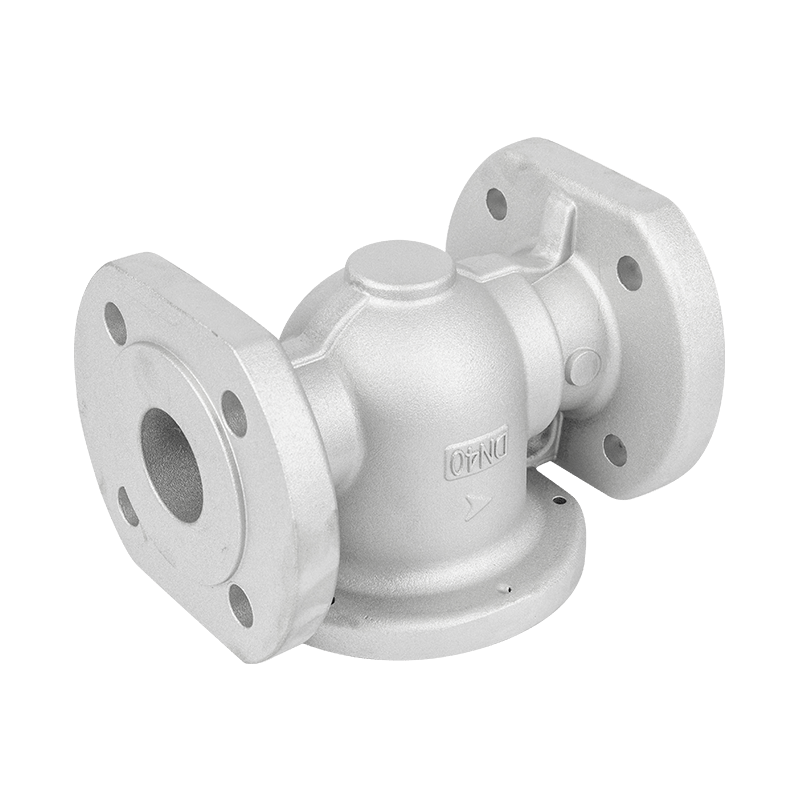

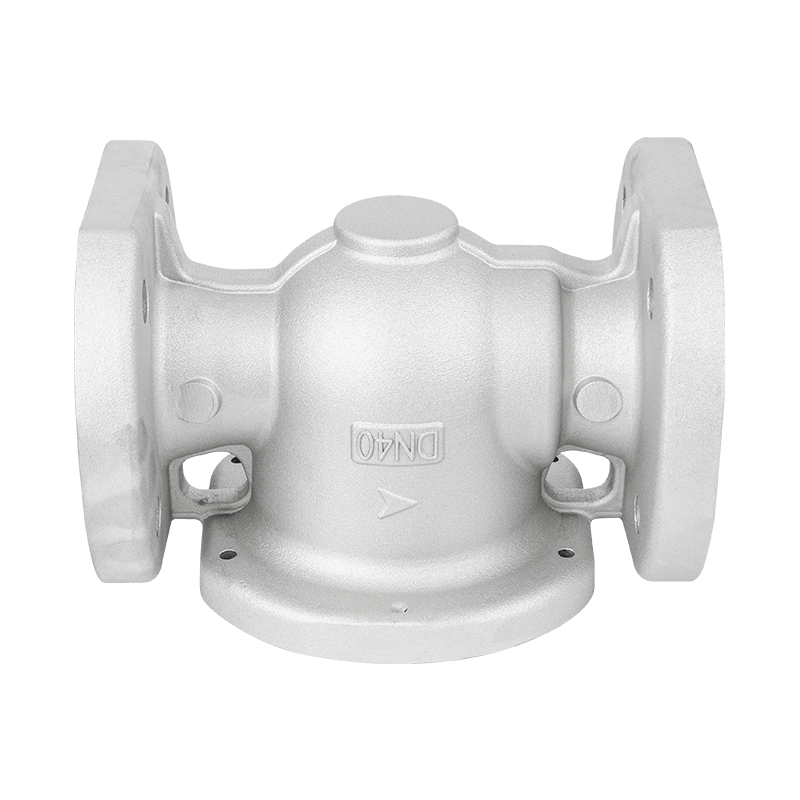

Part Usage: Industrial gas pipe valve body

Part Material: ZL101A

Manufacturing Technique: Low pressure die cast

Part Performance:

1. No leak allowed under2.4MPa;

2. No rust under SST 500H

3. Wall thickness is huge difference which lead the part easy to happen appearance defect.

Part Difficulty:

1. The profile is too big and wall thickness is huge difference which lead the part easy to happen appearance defect.

2. No leak allowed under pressure 2.4MPa.

Melt And Slag Removal

Die Casting

Machine Grinding

Fine Machining

Quality Control

Leak Testing

Shot Blasting

Packing and Pallet

High/low pressure die-casting processing more than 12 types of alloys

26 HPDC machines from 400T-1250T, 10 LPDC machines

Production process follows APQP, raw material purchase and testing--melt and slag removal--die casting--fine machining--leak testing--cleaning-packing

Annual processing capacity of 10,000 tons of aluminium die-casting

Over 20 CNCs, VMCs, HMCs, SPMs, etc.

Special purpose machines for large production

In-line leak testing and ultrasonic washing

Machining critical components for automotive transmission, engine, chassis, and other applications

Mold design and manufacturing including but not limited to

apply APQP process, and we currently use CAD, Pro/E, UG,

Anycasting software to support our designs.

Ningbo Zunhang Automotive Parts Co., Ltd. founded in 2012, is a large-scale enterprise integrating professional aluminum die casting mold design, mold manufacturing and aluminum die casting parts production.

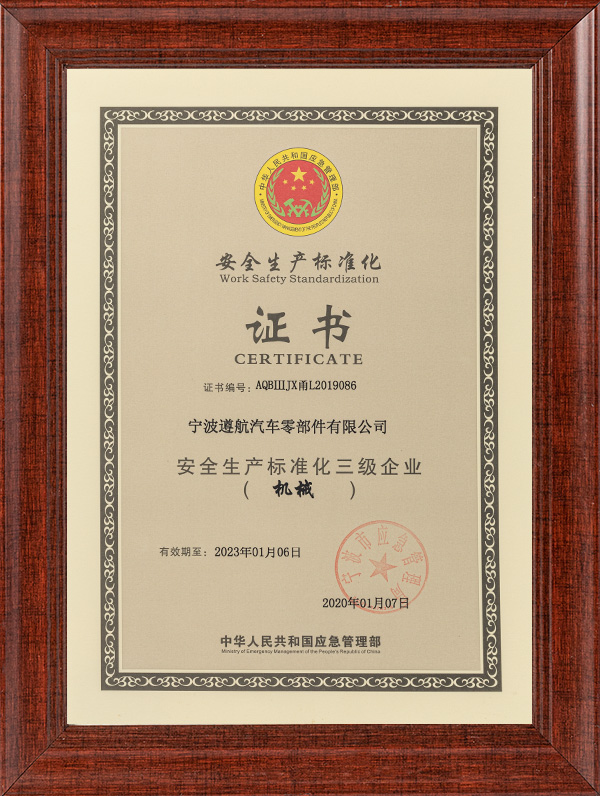

Zunhang gives full play to its team advantages and adheres to the business philosophy of "consistent words and deeds, dedicated service". The company successfully completed the certification of IATF16949 in 2018, All staff shall introduce "process risk management thinking and implement PDCA continuous improvement method". Professional DN40 Industrial Gas Pipe Valve Body Low manufacturer and exporter in China.

Zunhang invested in the establishment of its subsidiary Ningbo Hangjin Auto Parts Co., Ltd. in 2016. The company is located in Ningbo Xiangshan Chengdong Industrial Park. It is a manufacturing enterprise mainly engaged in low pressure casting, high pressure casting, gravity casting, squeeze casting and other processes, greatly expanding the scope of business development and improving the capacity delivery capacity.

Ningbo Zunhang Automotive Parts Co., Ltd is a comprehensive production enterprise, include aluminum die casting mold design and manufacturing, aluminum high/low die casting parts production and Fine machining process.

Compliance with standards IATF16949. APQP production process. Digital workshop production management system.

Shanghai Sanden, Aotecar, Changjiang Automobile Electronic, Sanyang Electronics, Dyne, Joyson Electronics

Ningbo, Shanghai

26 HPDC machines, 10 LPDC machines. 15 fine machining machines Annual processing capacity of 10,000 tons of aluminium casting. Monthly production of over 1.5 million components.

Aluminum Die Casting Auto A/C Compressor Parts, Auto Engine Accessories, Auto Drive System Parts, Electric Auto Accessories, CNC Machine Parts, Bridge Member, Heavy Truck Parts, etc.

30% in advance, then 70% balance after copy of the B/L.

Yes.

Global Dept. Manager

+86 180 0670 1230

1. Die-casting process and common sense of die-casting aluminum alloy materials...

Original Title: Market Potential and Development of Magnesium Alloy/Aluminum Al...

Aluminum die-casting parts are aluminum parts with different functions, which a...

For better design & manufacturing aluminum alloy die casting automotive par...

Designing an aluminum die casting mold for complex geometries requires careful c...