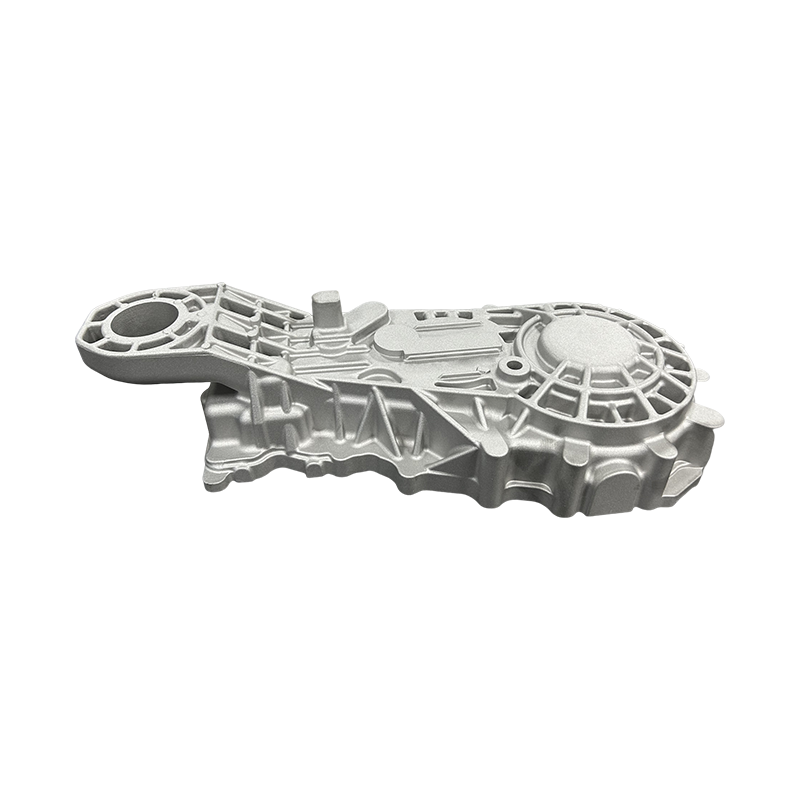

Aluminum high-pressure die-casting automotive parts can be used for the manufacturing of seat frames. The seat frame is an important component in car seats that carries and supports passengers, with strict requirements for its strength, rigidity, and weight. Aluminum alloy is gradually favored in the application of automotive seat frames due to its excellent lightweight, high strength, and corrosion resistance characteristics.

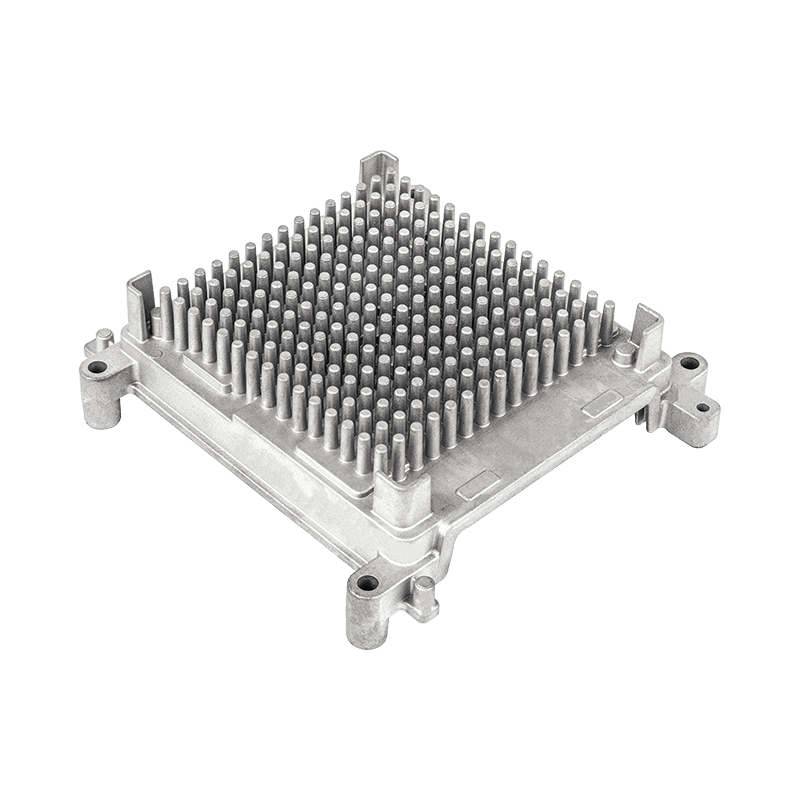

One major advantage of using aluminum high-pressure die-casting technology to manufacture seat frames is the ability to effectively reduce the overall weight of the seat. In modern automotive design, lightweighting has become a key factor in improving fuel efficiency and vehicle performance. Aluminum alloy has a lower density, which can significantly reduce the weight of the seat frame without affecting its required strength and safety, thereby improving the fuel economy and operational performance of the vehicle. Especially for electric vehicles, lightweighting the seat frame not only helps reduce the overall weight of the vehicle, but also enhances the battery's endurance.

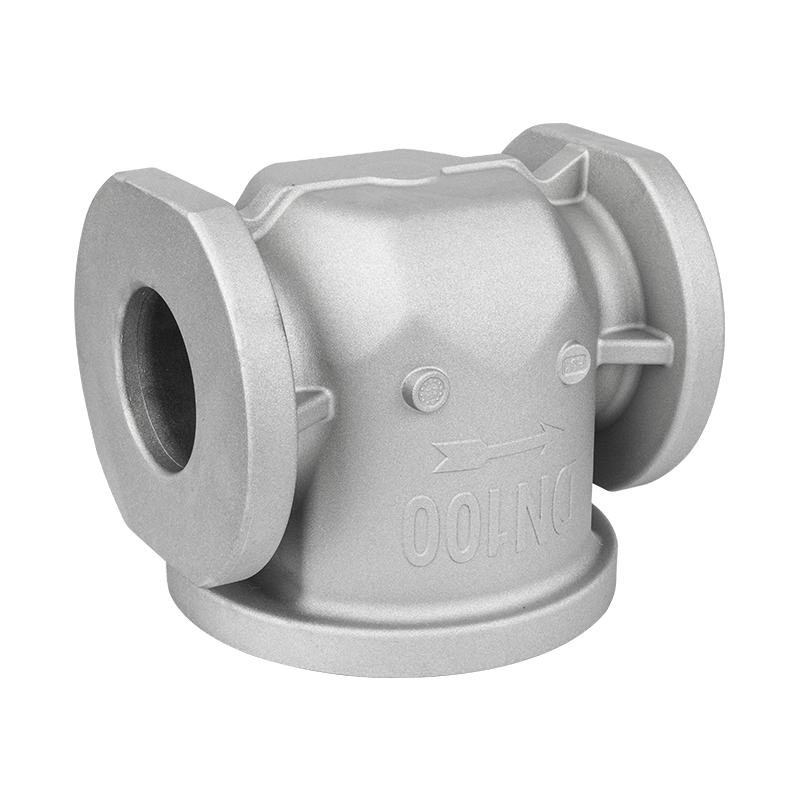

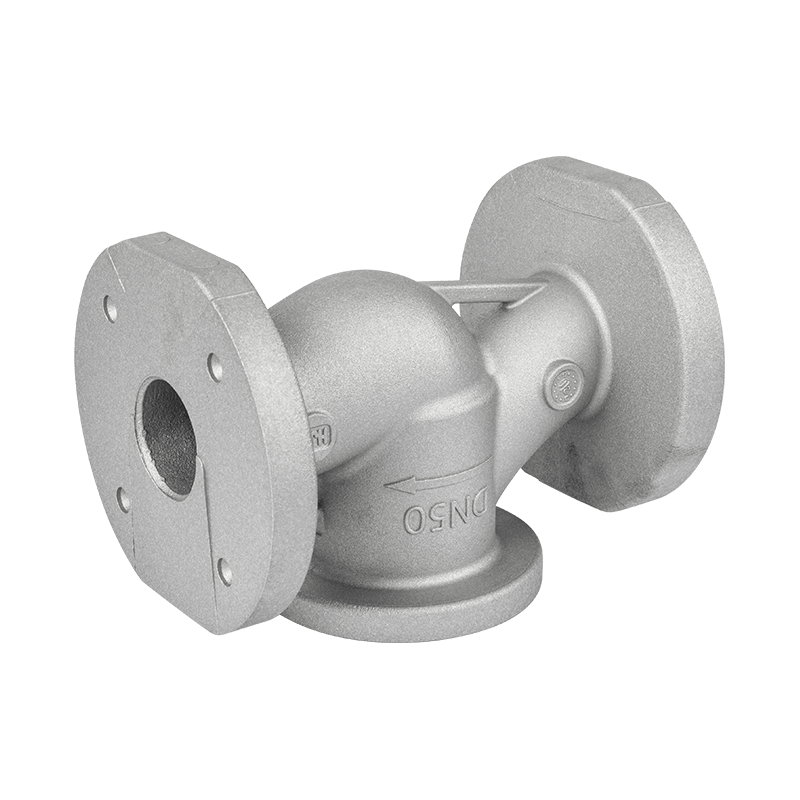

In addition, aluminum alloy has good corrosion resistance. After anodizing treatment, the surface hardness and wear resistance of aluminum alloy can be enhanced, allowing the seat frame to maintain its structural stability during long-term use. The seat frame is usually located in the interior environment of the car, but still needs to withstand sweat, moisture, dust, and occasional chemical erosion. The corrosion resistance of aluminum alloy can extend the service life of the seat frame, reduce corrosion problems during long-term use, and ensure a clean and comfortable interior environment.

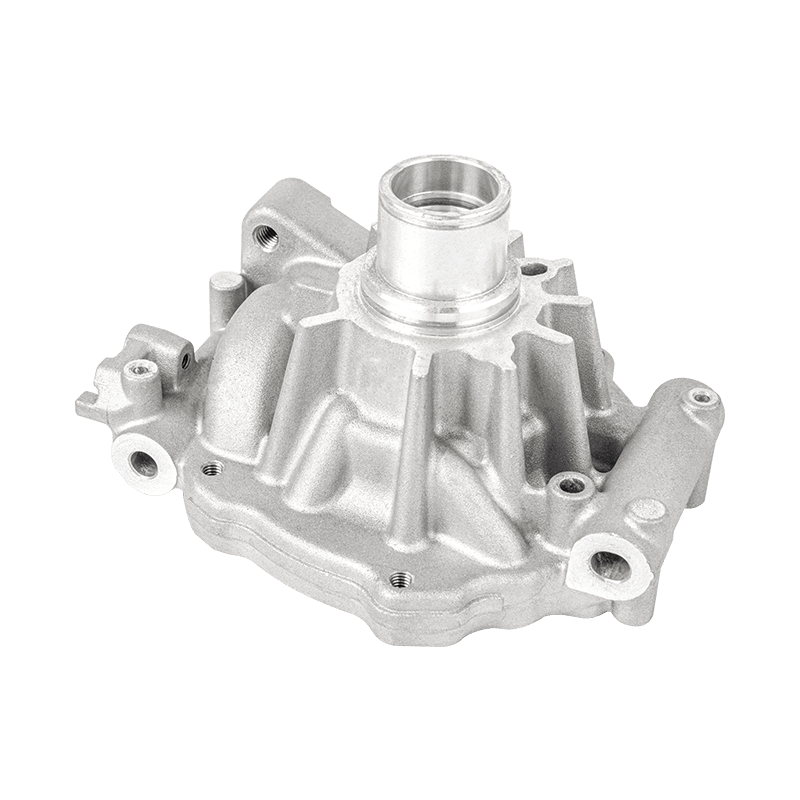

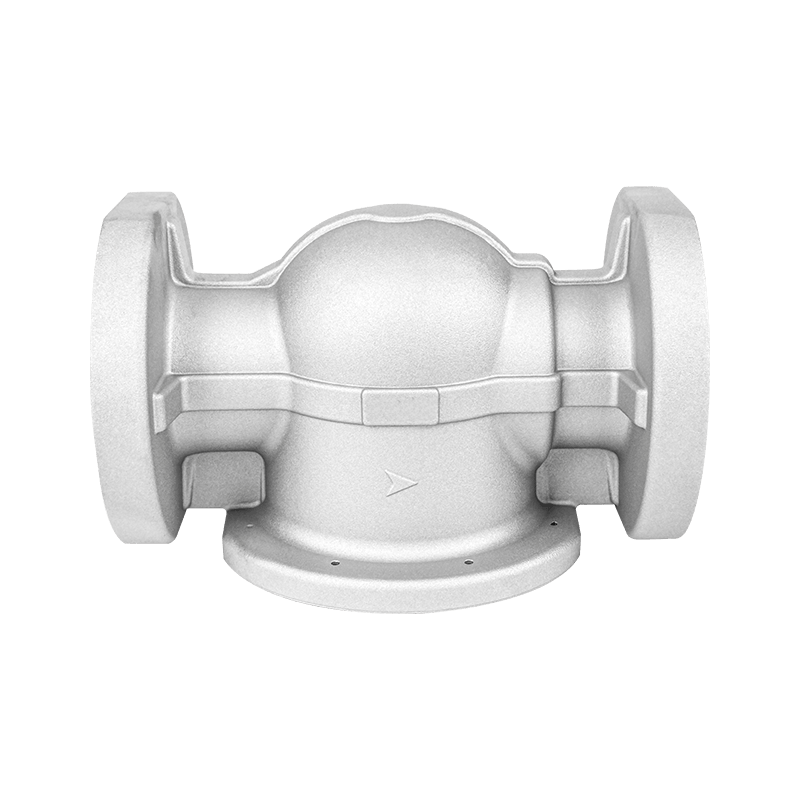

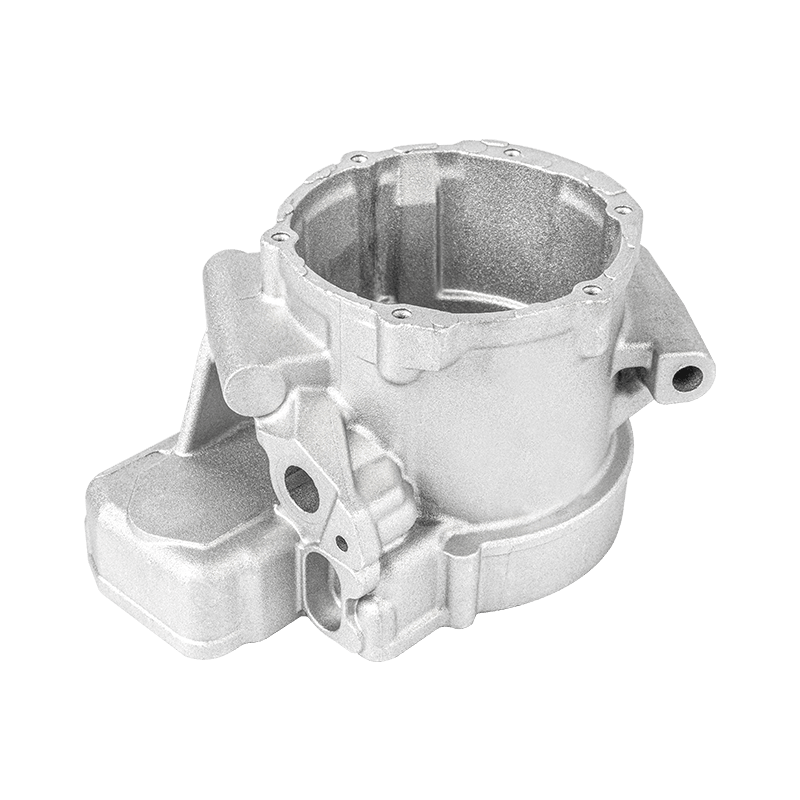

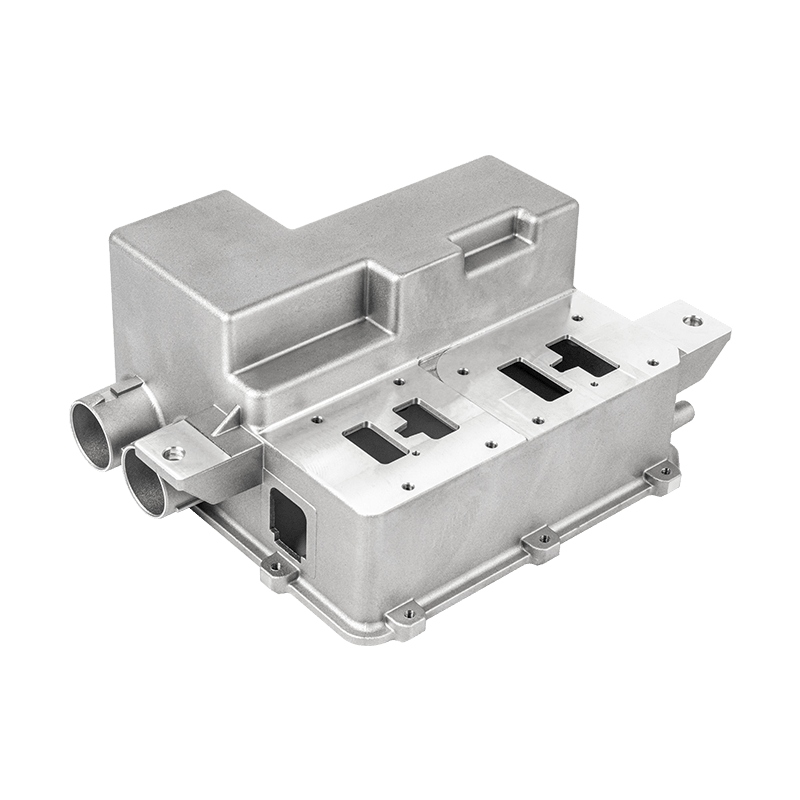

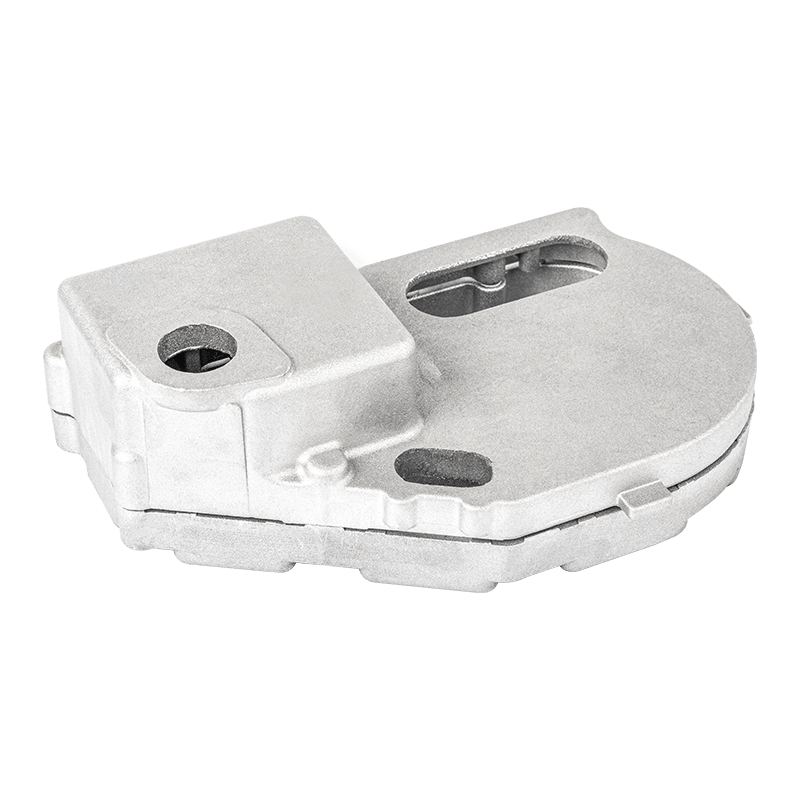

The aluminum high-pressure die-casting process can also achieve complex geometric shapes, which is very important for the design of seat frames. By die-casting, it is possible to integrate more functions and enhance the structural strength of the seat frame without increasing the number of components. For example, the die-casting technology of aluminum alloy can create complex support structures, making the seat frame more sturdy while maintaining lower weight. This design flexibility enables the application of aluminum high-pressure die-casting components in seat frames to better meet the structural and safety requirements of modern automotive design.