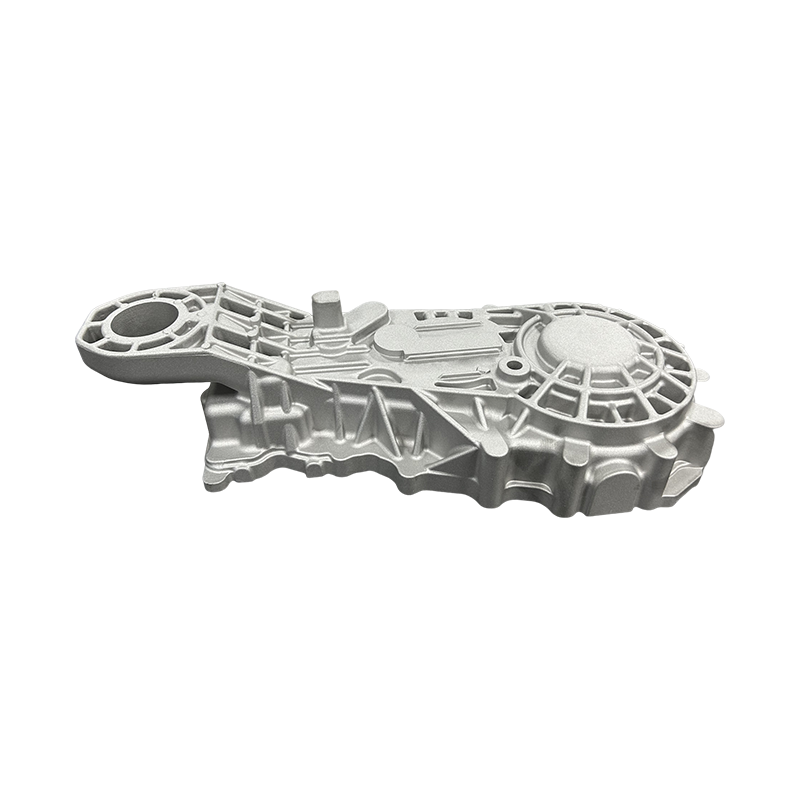

When manufacturing aluminum high-pressure die cast automotive parts, it is indeed necessary to optimize the alloy composition, which is a key step to ensure the performance, quality, and reliability of the parts. High pressure die casting is different from traditional casting methods in that it requires alloy materials to be rapidly filled and solidified under high pressure and high speed conditions. Therefore, higher requirements are put forward for the flowability, thermal cracking resistance, mechanical strength, wear resistance, and casting defect control ability of the alloy. In order to meet the multiple performance indicators of automotive components in terms of strength, durability, processability, and environmental adaptability, it is necessary to finely adjust and optimize the composition of aluminum alloys according to specific usage locations and working conditions.

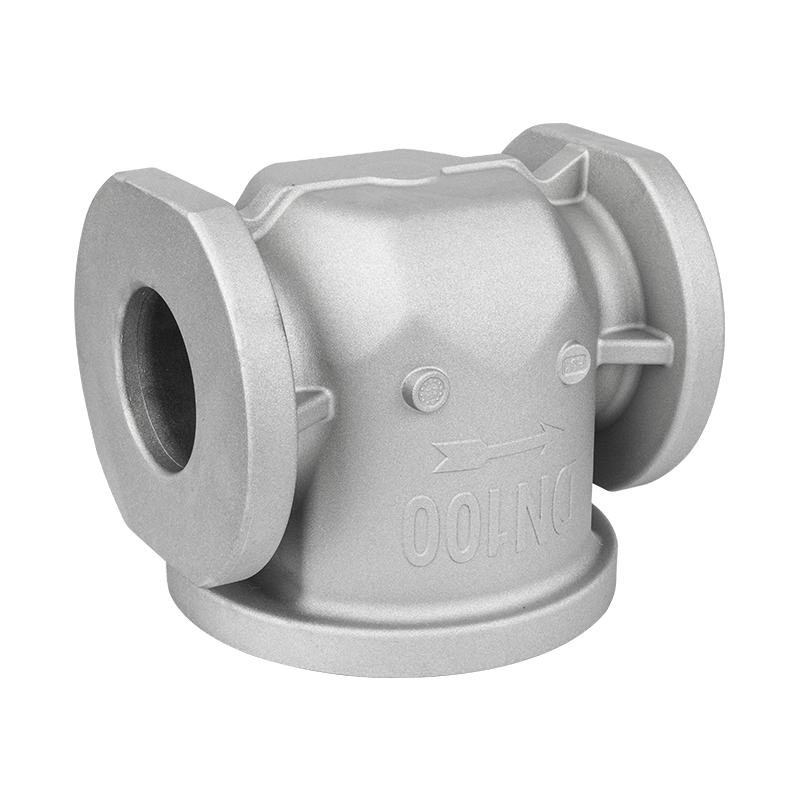

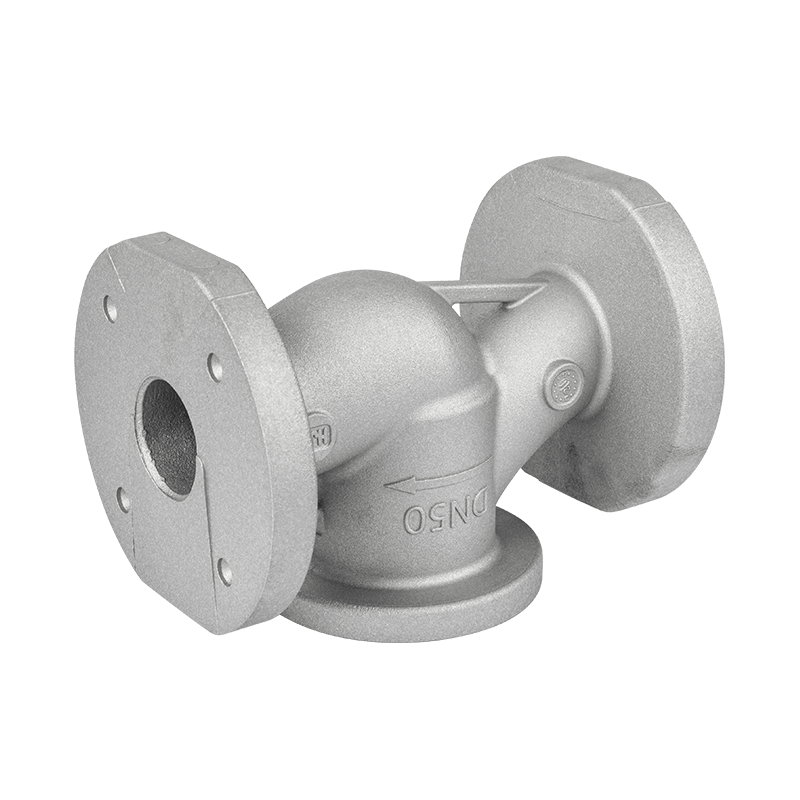

Common aluminum high-pressure die-casting alloys such as ADC12 (Al Si Cu series), A380, etc. are made by adding elements such as silicon, copper, magnesium, iron, zinc, etc. to the base aluminum alloy, and improving the comprehensive performance of the material by adjusting the content of each element. For example, silicon can improve the fluidity and heat resistance of alloys, copper and magnesium help enhance strength and hardness, while the addition of iron can improve heat cracking resistance, but excessive content can reduce toughness, so its proportion needs to be strictly controlled. In addition, in order to improve corrosion resistance and suppress intergranular corrosion, it is sometimes necessary to add trace amounts of manganese, titanium, or rare earth elements.

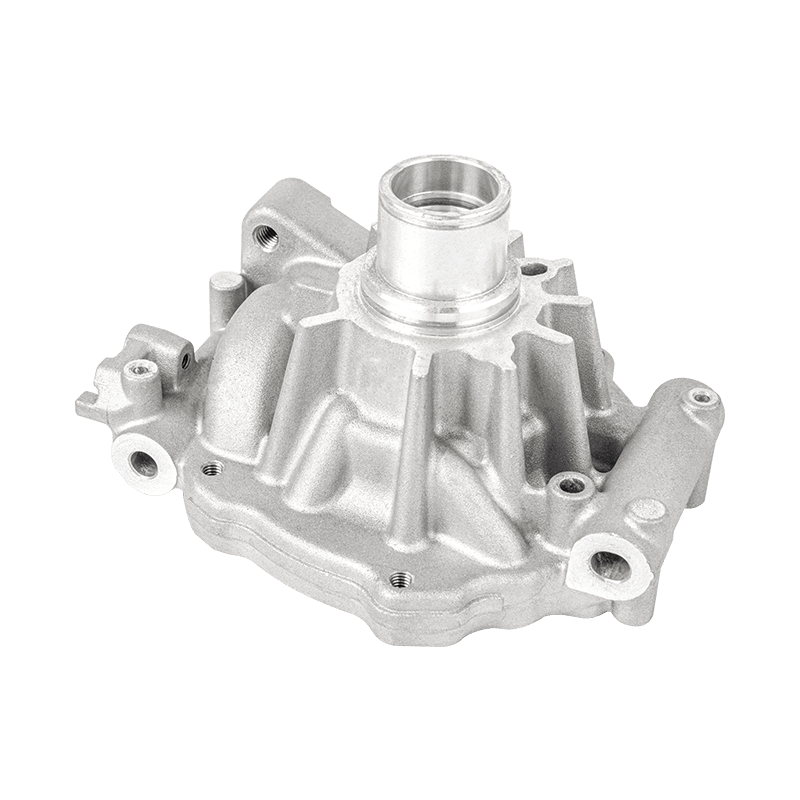

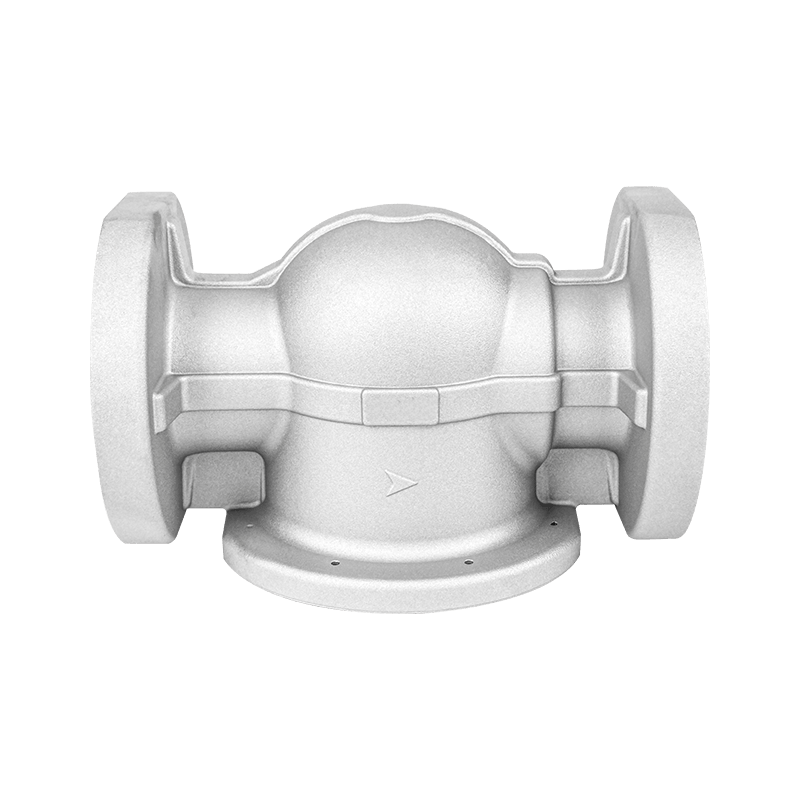

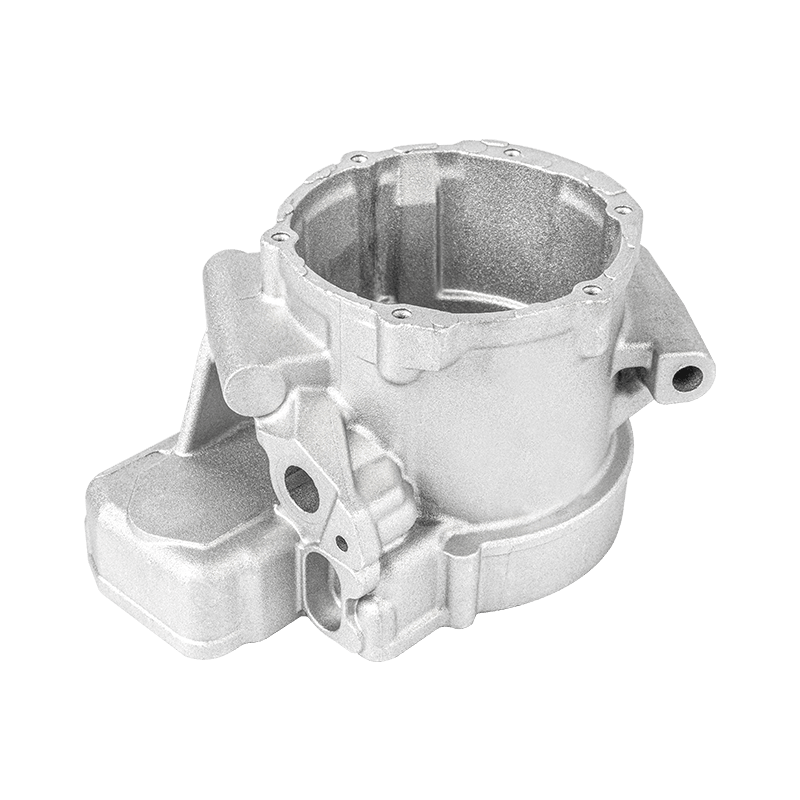

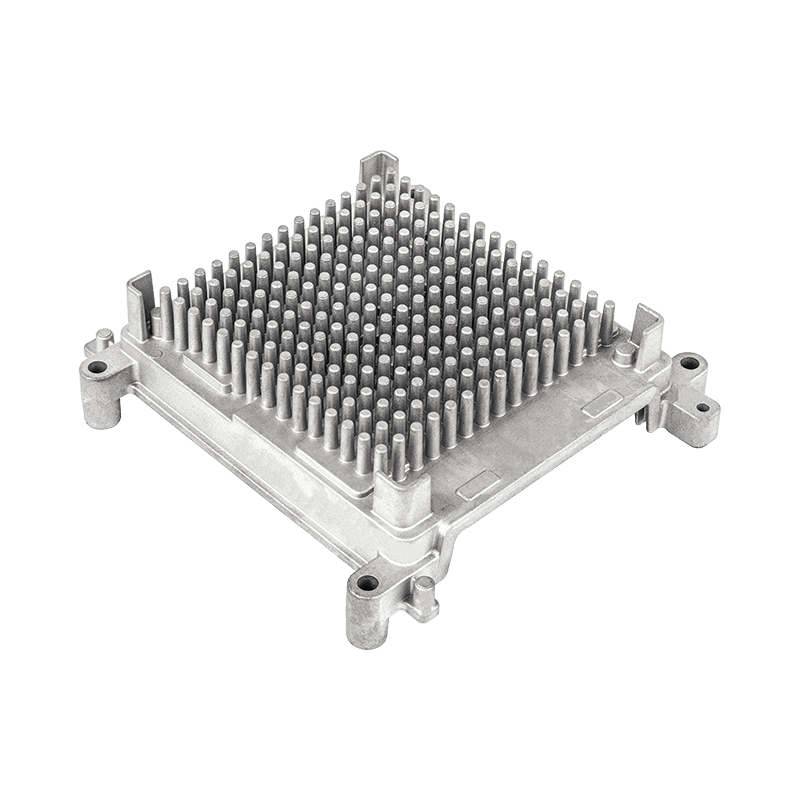

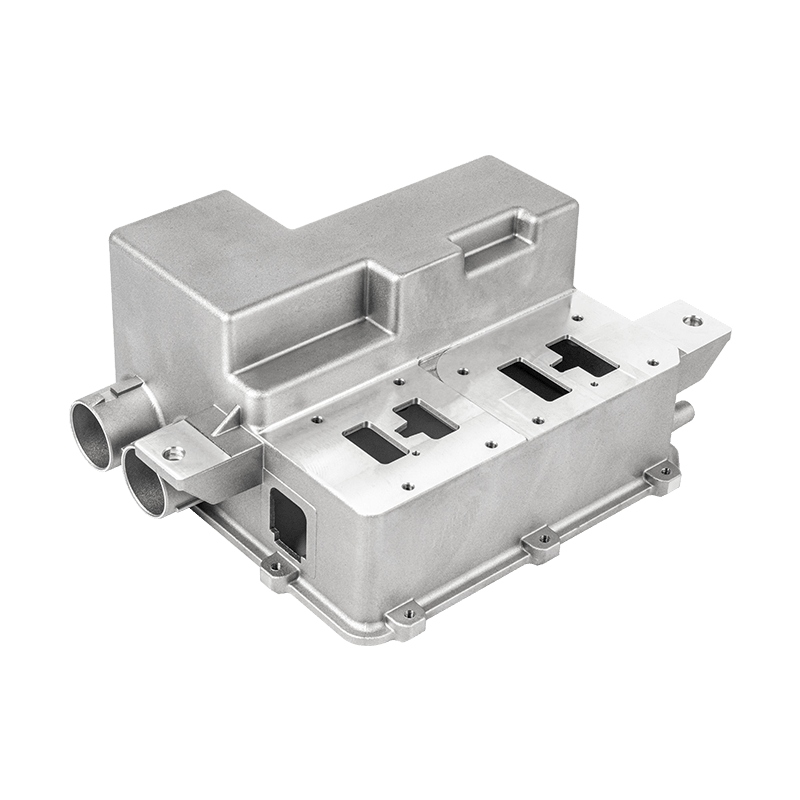

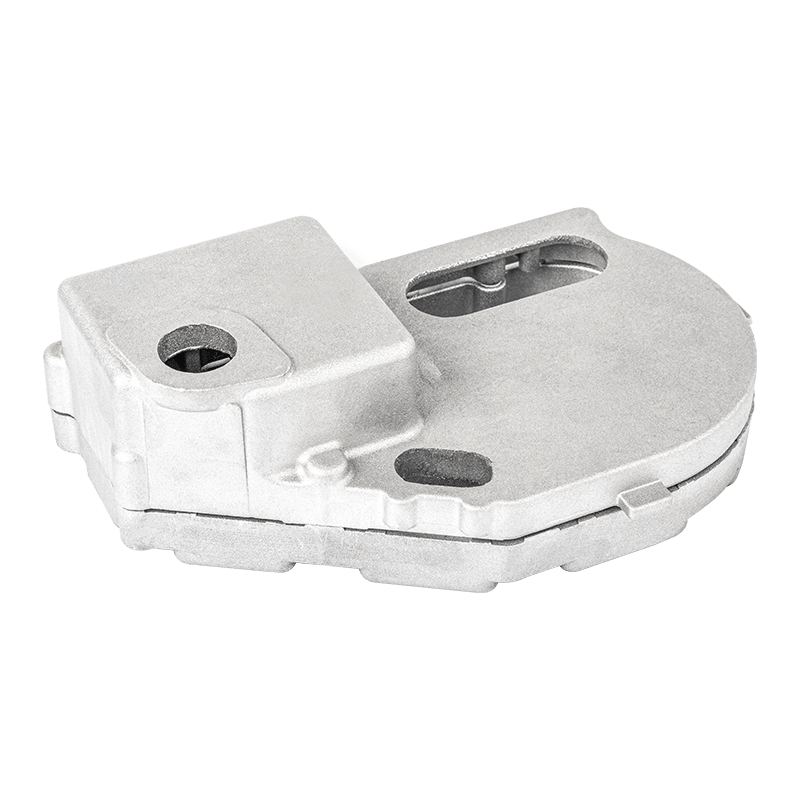

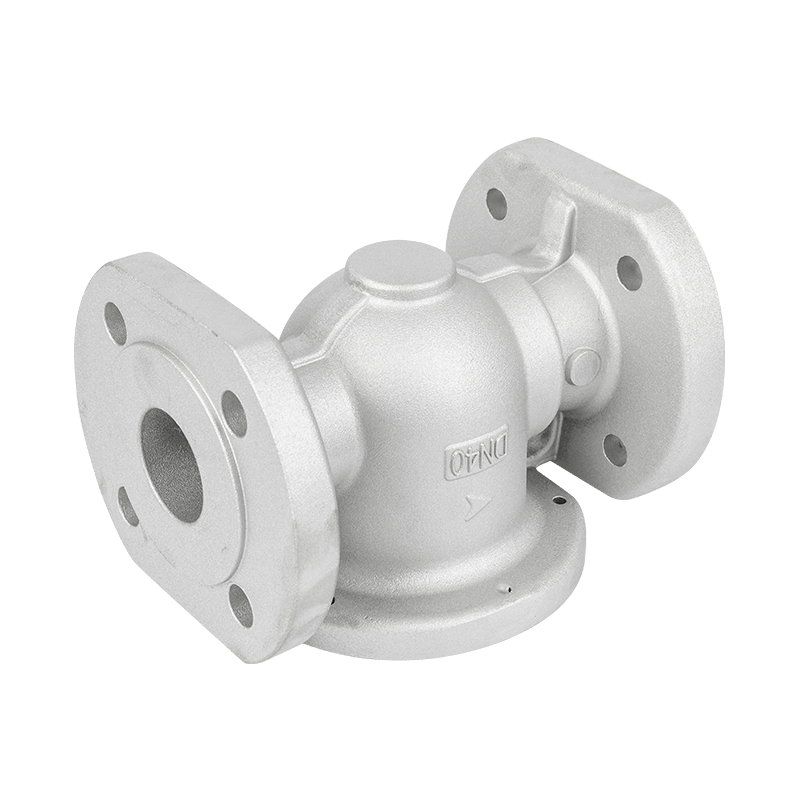

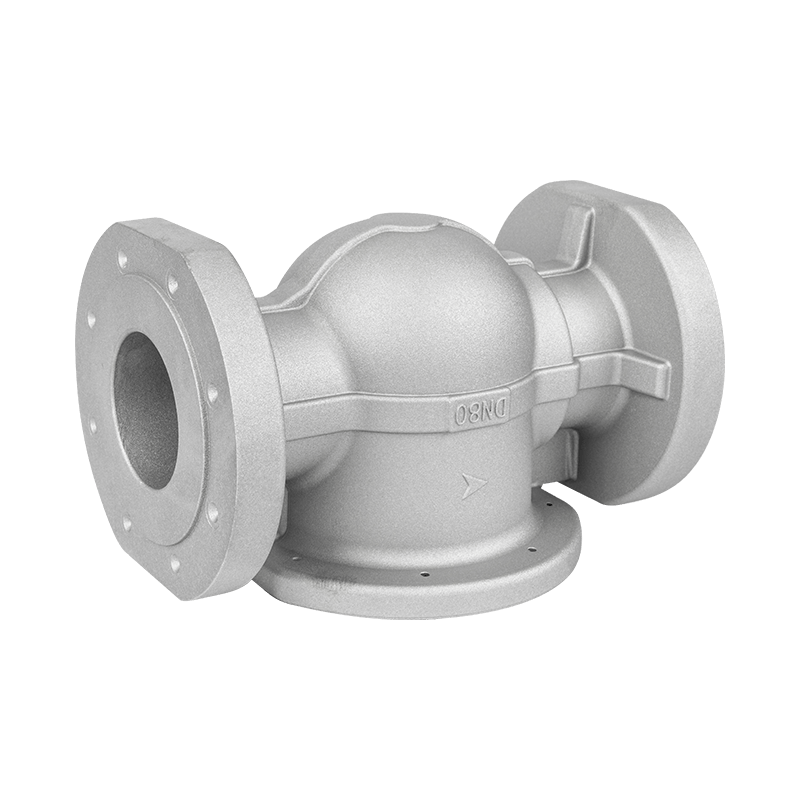

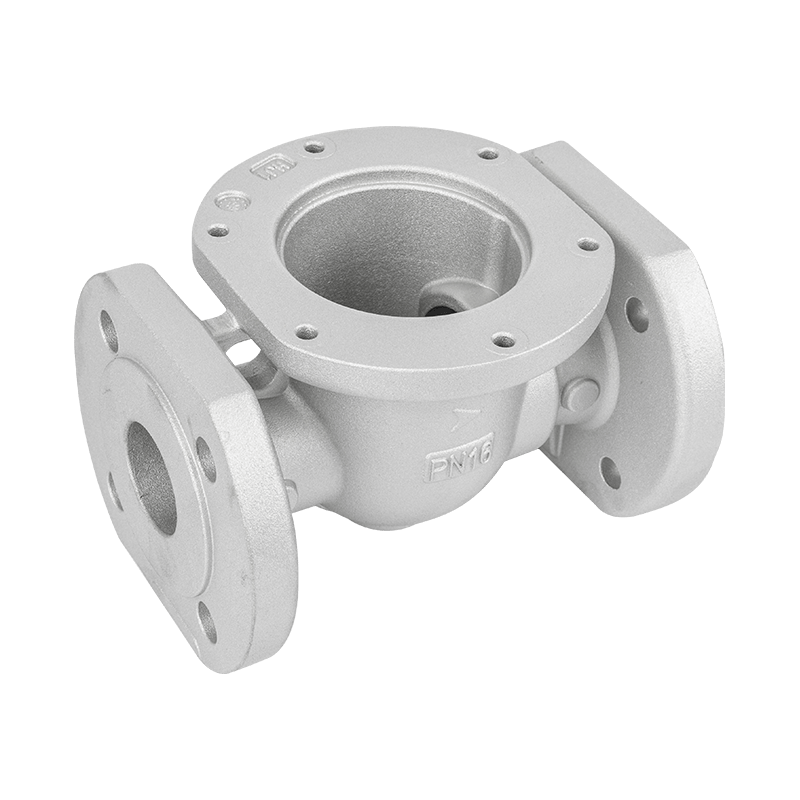

Optimizing alloy composition can not only improve the casting yield of parts, reduce casting defects such as porosity and shrinkage, but also ensure the stability and consistency of parts during service. For example, aluminum alloys used in high load and high safety areas such as engine casings, suspension brackets, seat frames, or crash beams must have excellent fatigue performance, impact toughness, and resistance to thermal deformation, all of which are closely related to the chemical composition of the alloy. Therefore, developing specialized alloy formulas for different product requirements has become an important trend in the manufacturing of high-end aluminum die-casting parts.

With the increasing attention of the automotive industry to sustainability and green manufacturing, alloy optimization also needs to balance environmental protection and recyclability. The use of certain elements in alloys should minimize their impact on the environment and ensure that they can be easily recycled and reused after the end of the component's lifespan, without affecting the quality of recycled aluminum.

The optimization of alloy composition is not only a technical means to improve process stability and part performance in the manufacturing of aluminum high-pressure die cast automotive parts, but also an important guarantee to promote product lightweighting, energy conservation and emission reduction, and extend service life. It directly affects the overall quality of automobiles and the market competitiveness of manufacturing enterprises.