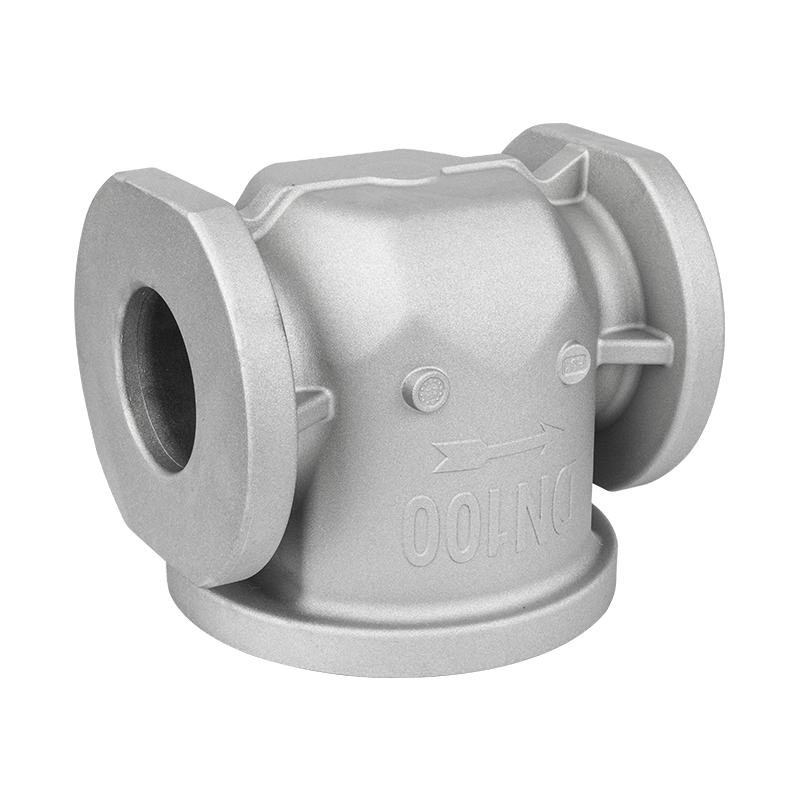

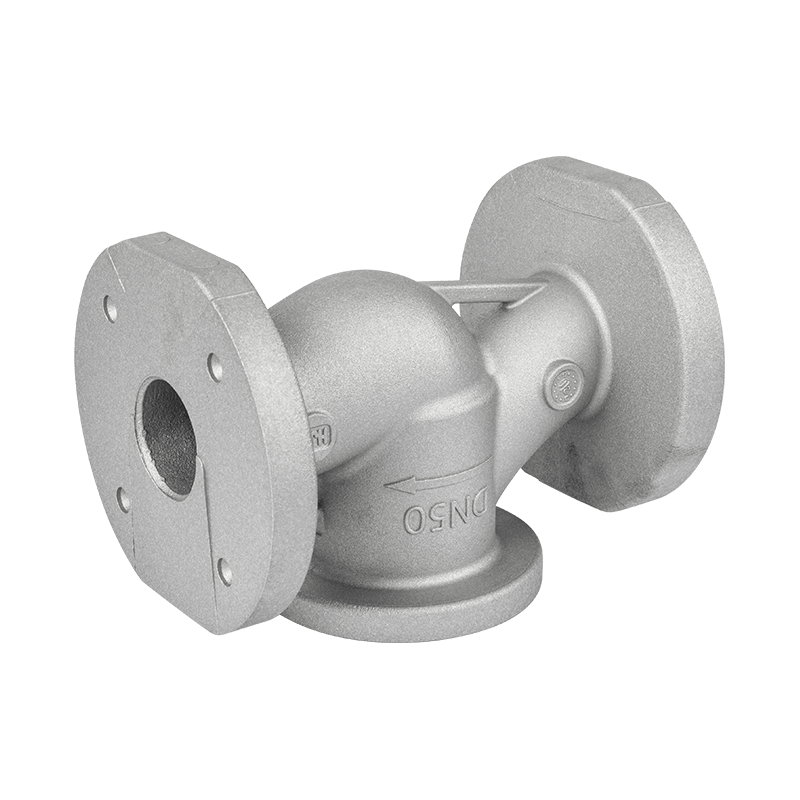

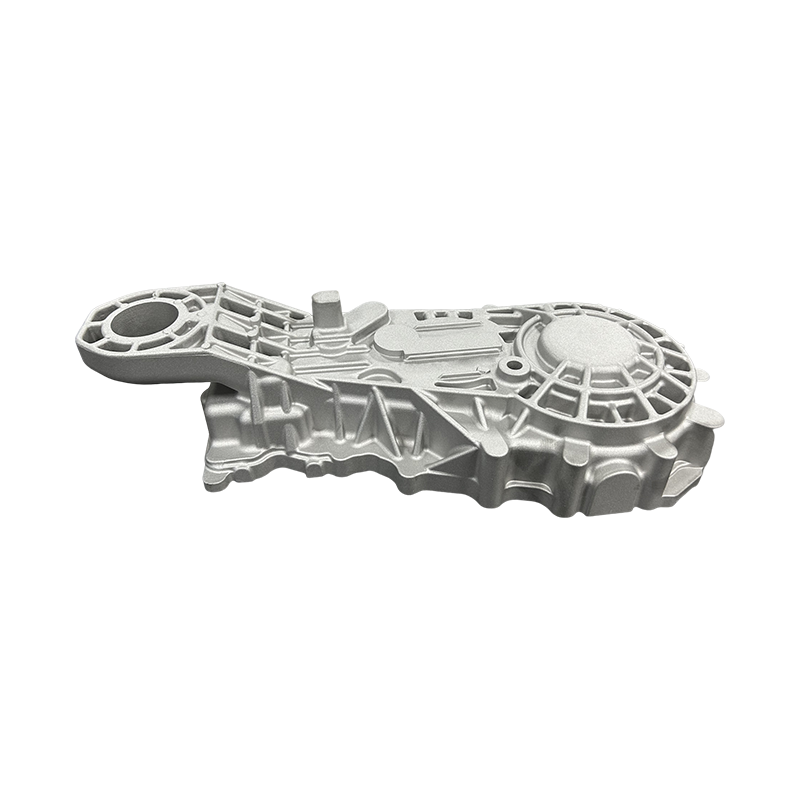

Aluminum low pressure die-casting automotive parts usually require deterioration treatment to improve their performance and meet the stringent requirements of automotive parts during use. Deterioration treatment is the process of improving the structure and properties of aluminum alloys by appropriate heat treatment or adding specific elements, resulting in higher strength, corrosion resistance, and better fatigue life. The aluminum low pressure die-casting process itself requires aluminum alloys to have good fluidity and low casting defects, and modification treatment can further optimize the performance of aluminum alloys on this basis, ensuring that parts can maintain stable working conditions under high temperature, impact, and long-term use.

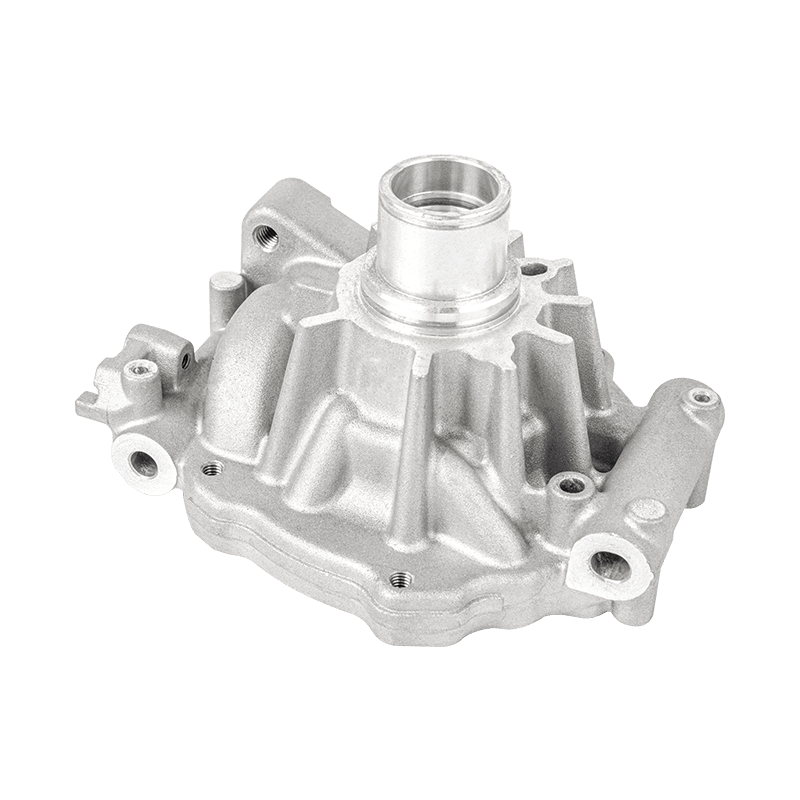

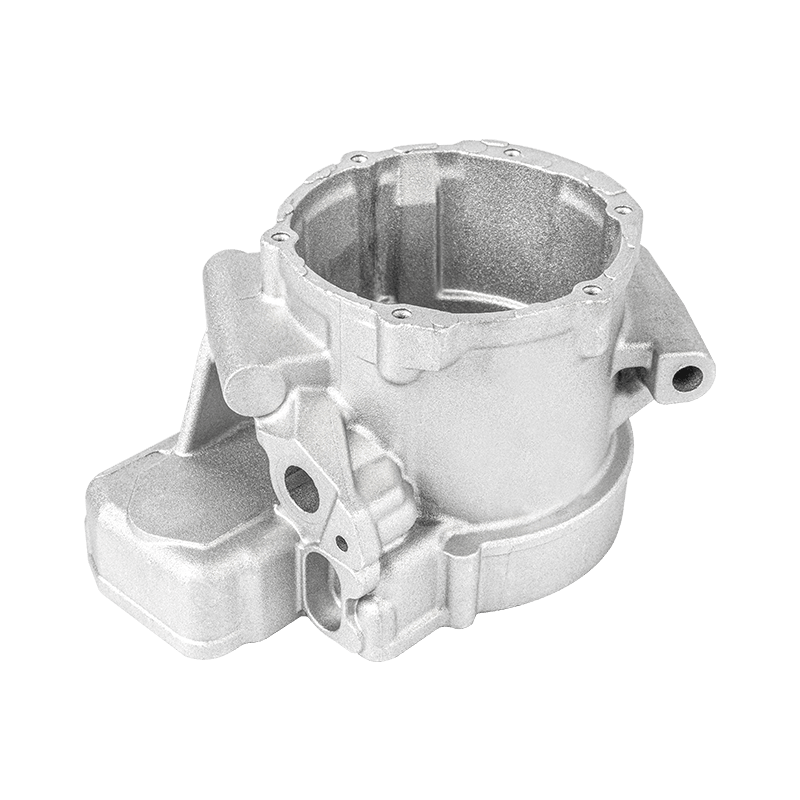

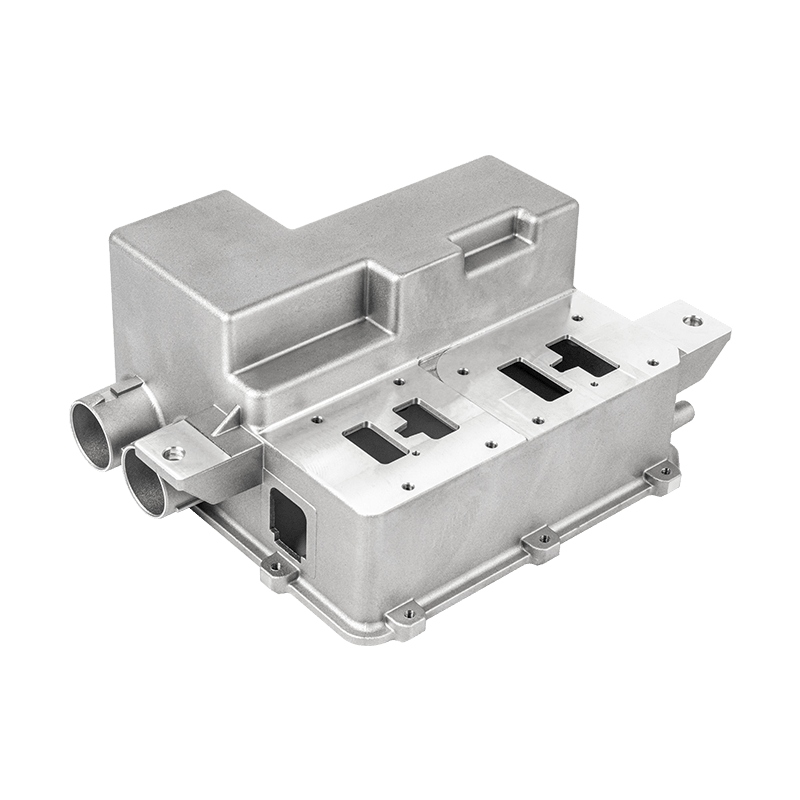

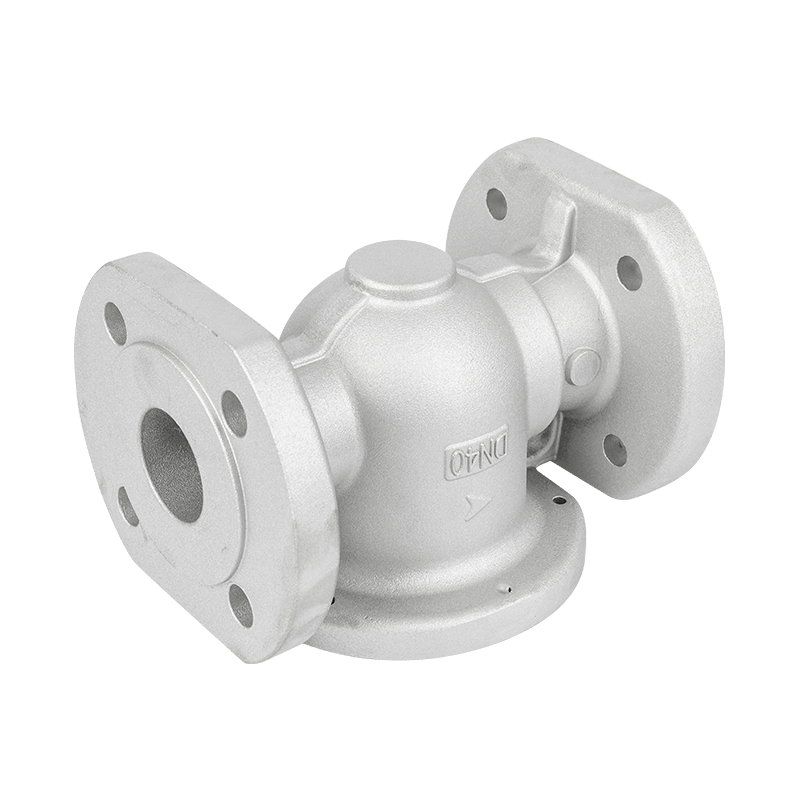

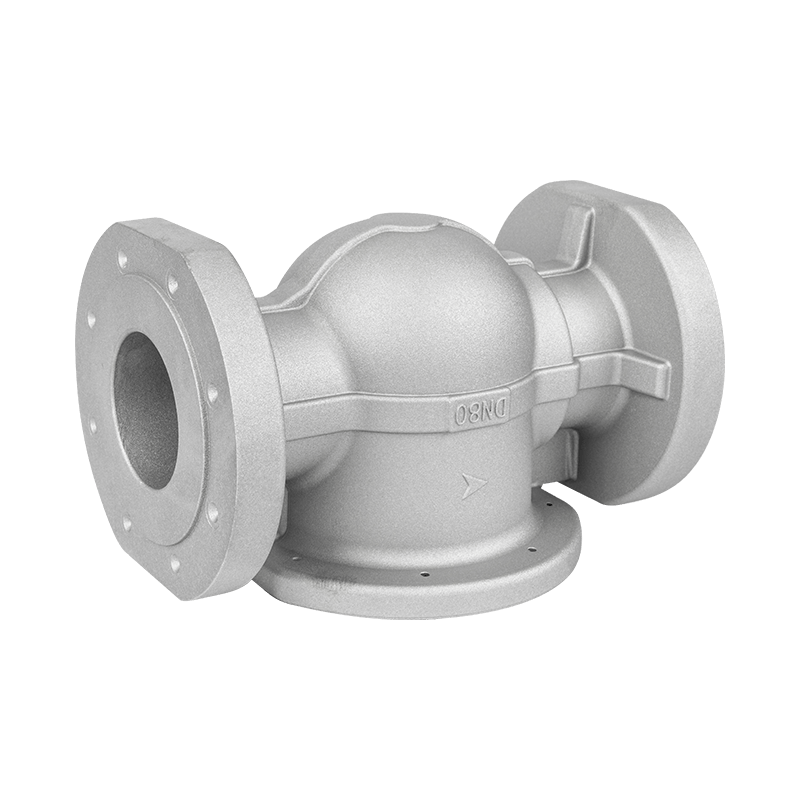

In aluminum low pressure die-casting, aluminum alloy can increase the strength and hardness of the material through heat treatment (such as aging treatment) after casting, which is crucial for automotive parts that need to withstand high loads, frequent vibrations, and constantly changing temperatures. Aging treatment causes the precipitation of strengthening phases in the alloy, thereby enhancing its mechanical properties, tensile strength, and fatigue resistance. This treatment is particularly important for high-strength parts such as engine casings and gearbox casings. The alloy composition of aluminum alloy is carefully adjusted during the manufacturing process, such as adding elements such as silicon, copper, magnesium, manganese, etc., which can further optimize its performance, improve its castability, corrosion resistance, and mechanical strength, thereby ensuring the reliability and service life of automotive parts in use.

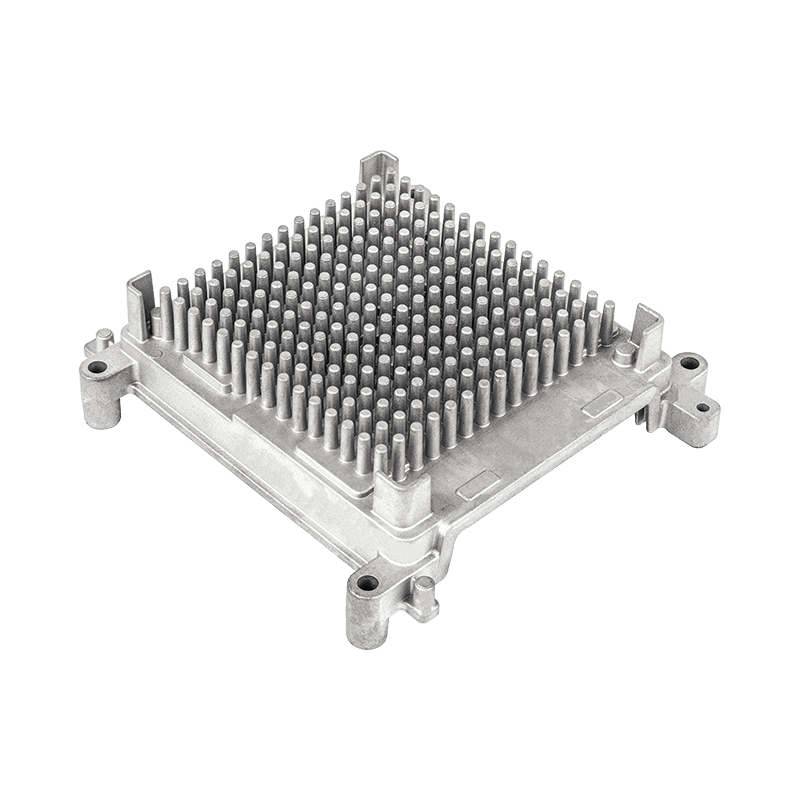

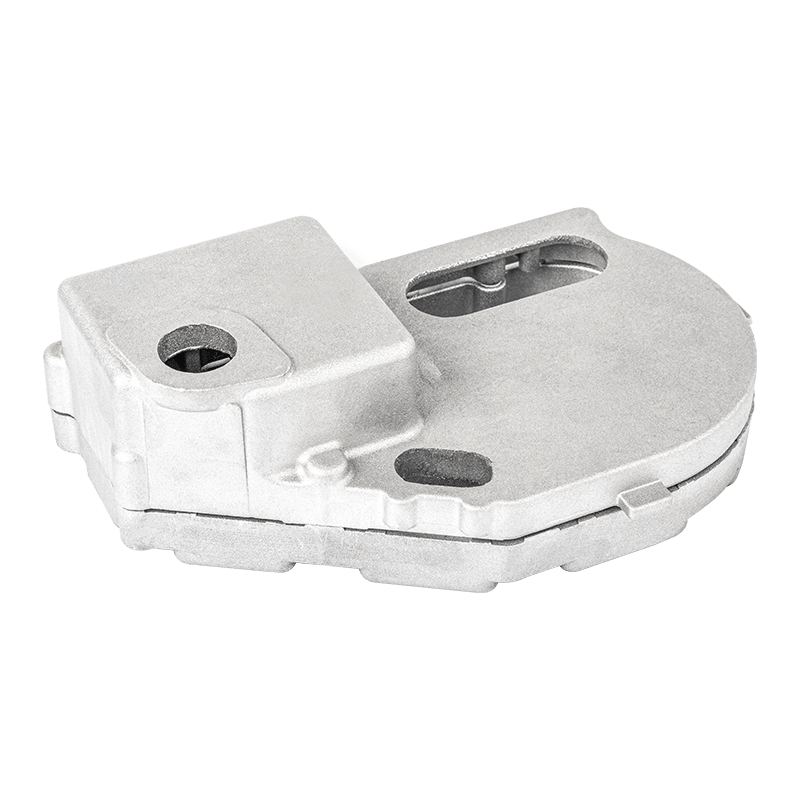

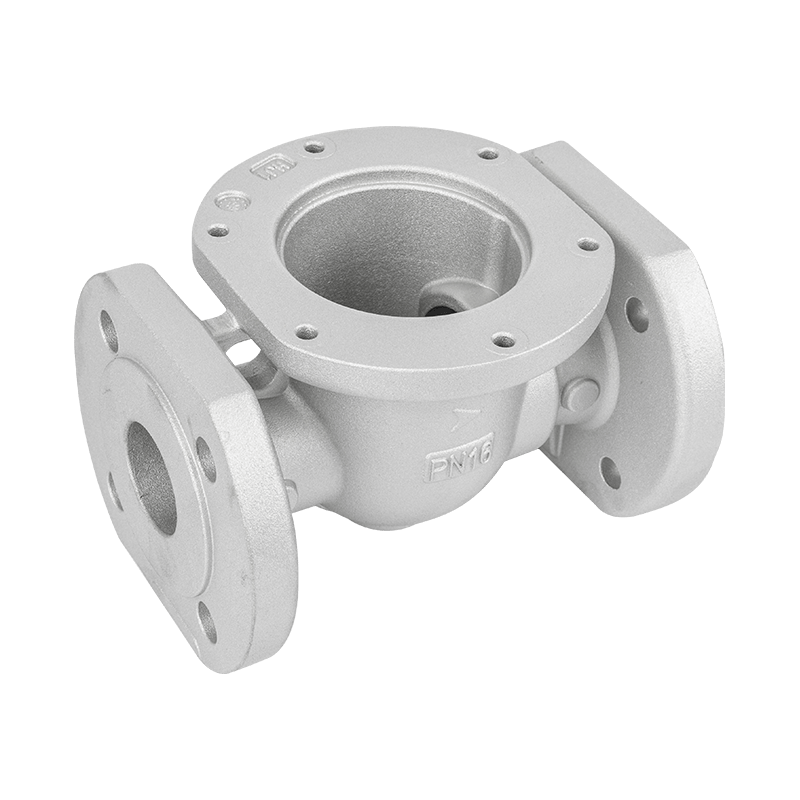

In order to improve the corrosion resistance of parts, especially those exposed to moisture, salt spray, or other corrosive environments, aluminum low pressure die-casting parts are often subjected to surface treatment. Common surface treatment methods include anodizing, electroplating, coating, etc. These methods can increase the hardness of the part surface, form a protective film, avoid corrosion of the part in harsh environments, and thus extend its service life. Grain refinement treatment is also a part of modification treatment, which can improve the comprehensive mechanical properties of aluminum alloys, enhance their strength, toughness, and fatigue resistance, and make aluminum low pressure die-casting parts more adaptable to high-strength and long-term working conditions.