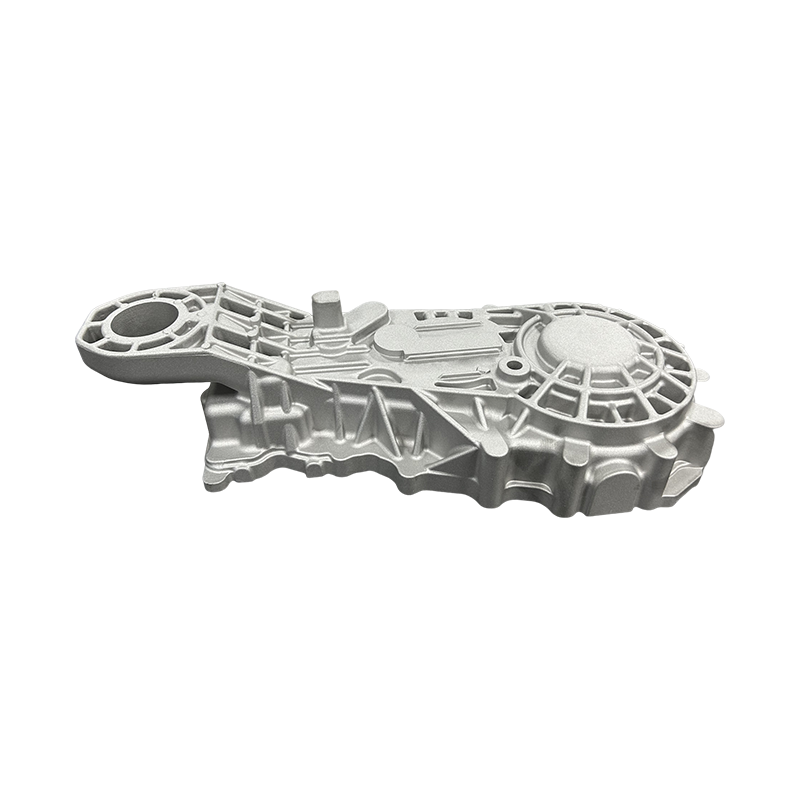

Aluminum low-pressure die-casting automotive parts can be used for sub frames, and the following is a detailed introduction to their applicability:

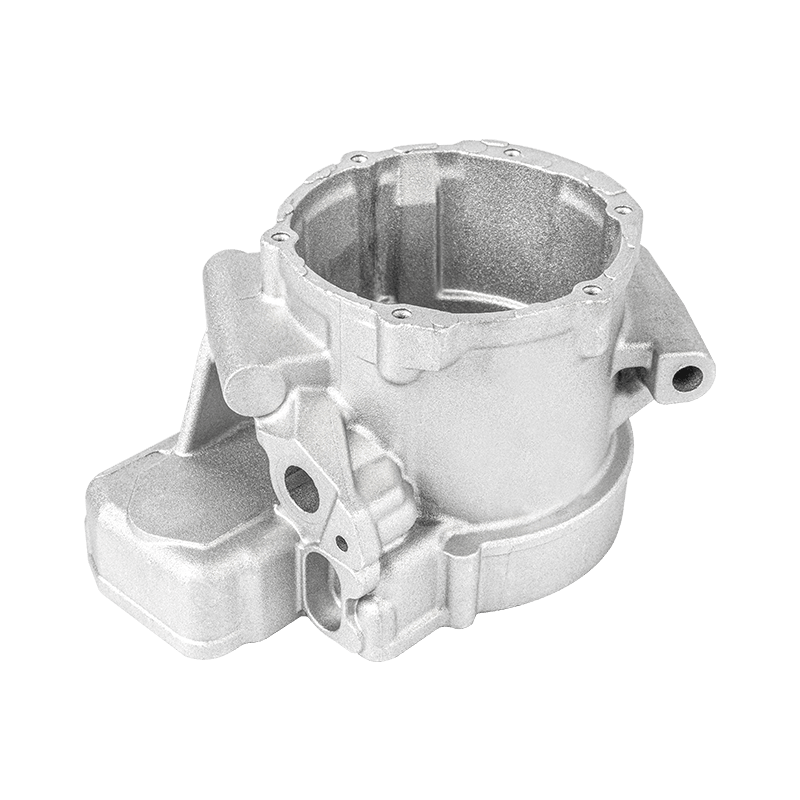

1. Lightweight and conducive to lightweighting: Aluminum alloy has low density, and the weight of the subframe parts produced by low-pressure die-castinging is significantly lower than that of traditional steel structures, which helps to reduce the overall weight of the vehicle, improve fuel economy and electric vehicle range.

2. Excellent mechanical properties: Aluminum low-pressure die-castingings that have undergone deterioration and heat treatment have good strength, rigidity, and impact resistance, which are sufficient to withstand various loads and impact forces that the subframe can withstand during driving and meet structural strength requirements.

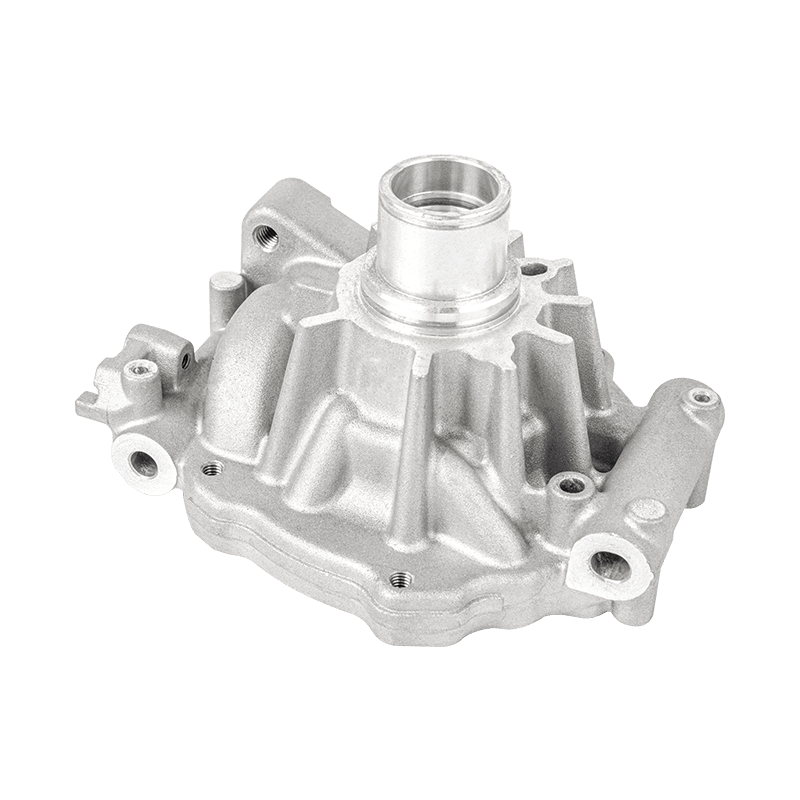

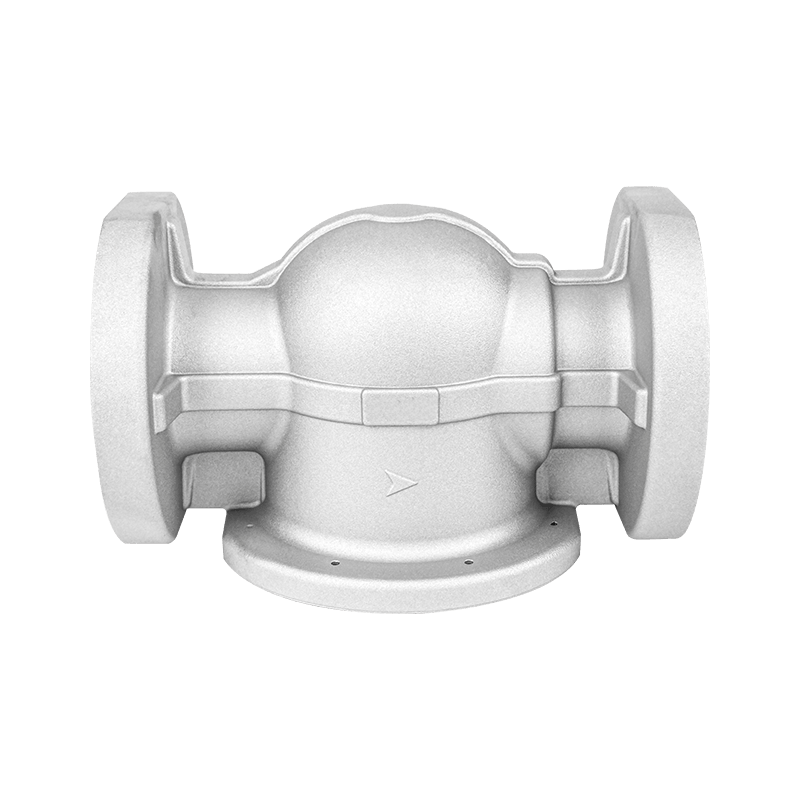

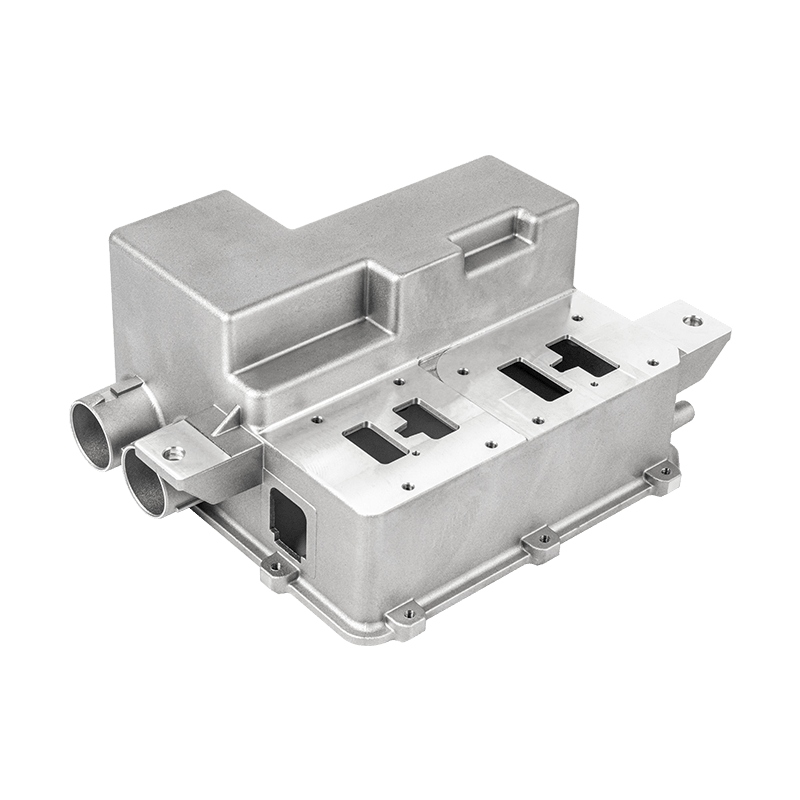

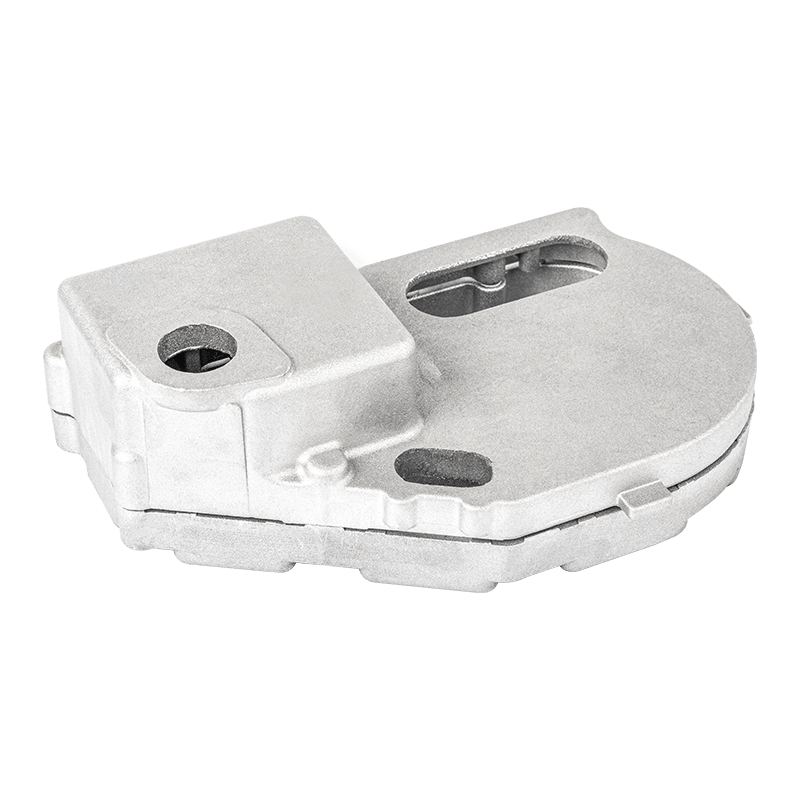

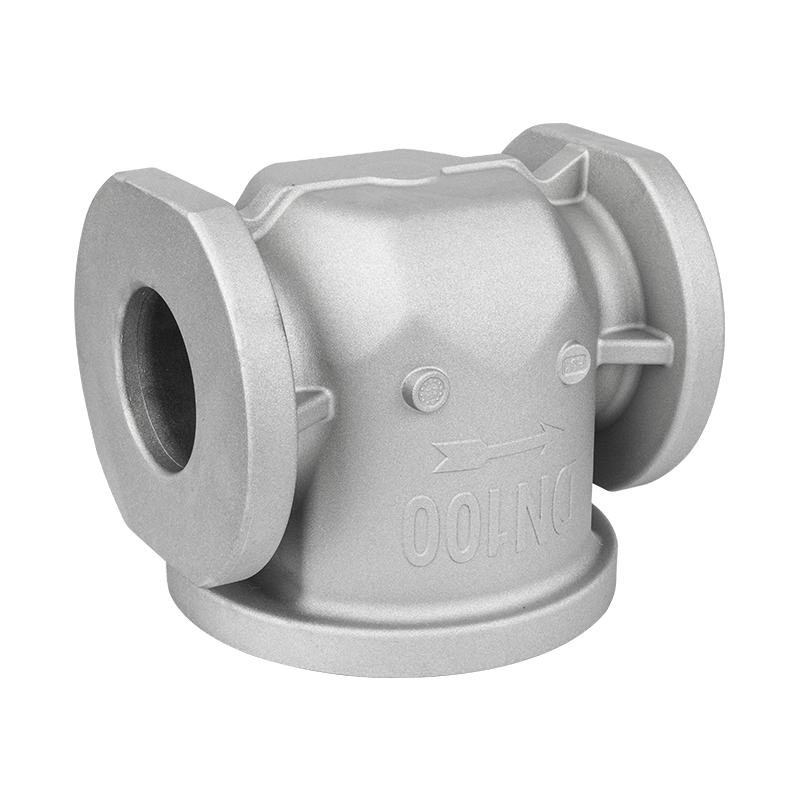

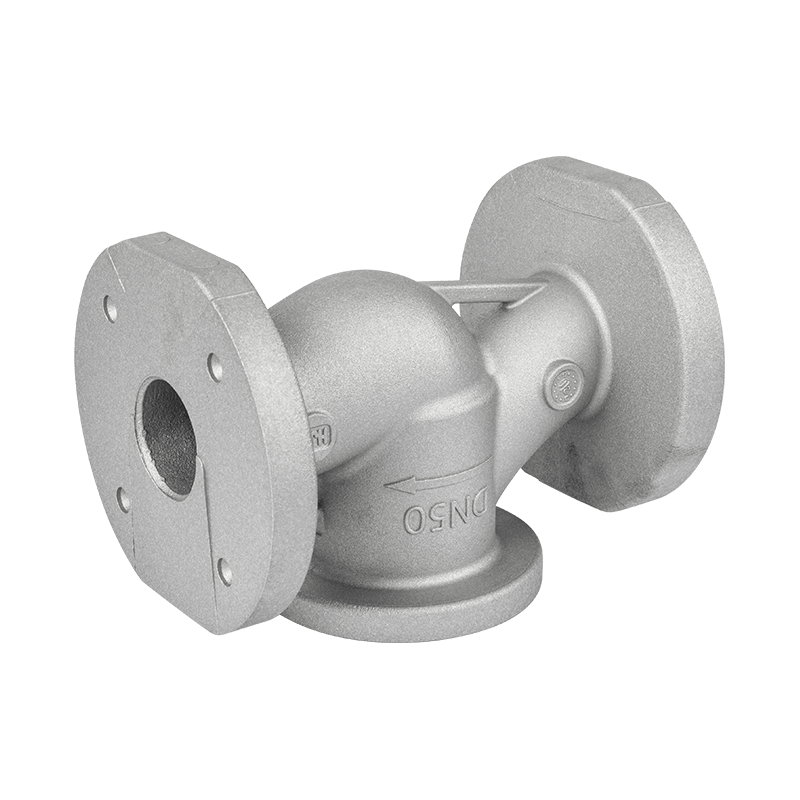

3. High molding accuracy and flexible design: Low pressure die-castinging technology can manufacture integrated structural subframe components with complex shapes and high dimensional accuracy, which is conducive to reducing welding and assembly links, improving structural integrity and consistency.

4. Strong corrosion resistance: Aluminum alloy has good corrosion resistance characteristics. After surface treatment (such as anodizing), it can effectively resist corrosive environments such as rainwater and salt spray, extending the service life of the subframe.

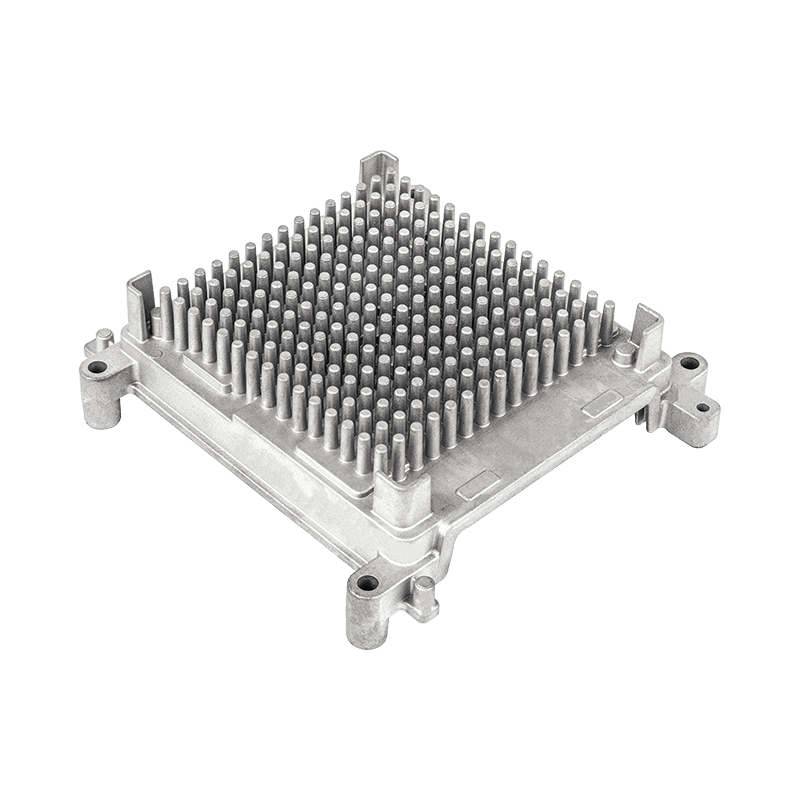

5. Good vibration absorption and noise reduction: The internal structure of aluminum low-pressure die-castingings is dense and moderately rigid, which can effectively reduce vibration and noise during vehicle driving, and is conducive to improving ride comfort.